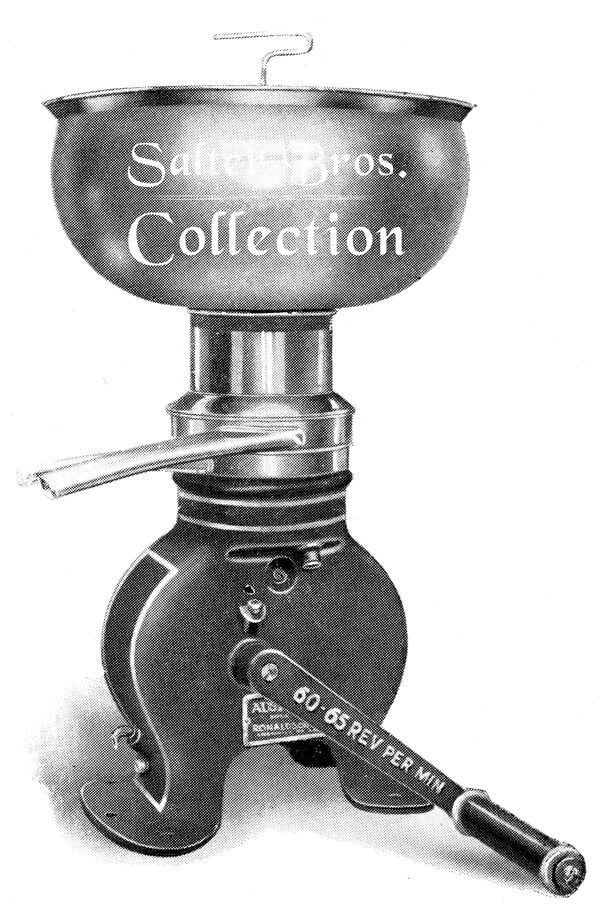

Ronaldson Tippett Cream Separator

The outstanding quality of the -Ronaldson-Tippett Separator ensures to you the highest possible skimming results combined with long life and a minimum of duplicates.

Every possible refinement in design is embodied in this latest production of a firm whose name is a household word throughout the world, a firm whose Separator pro-ducts are a standard of comparison for all others.

The new Ronaldson-Tippett carries our most definite and binding guarantee of lasting and complete satisfaction. It is a machine that we can gladly recommend with the utmost confidence to our oldest clients.

The outstanding simplicity of this new Separator is a feature of considerable interest to users not only does it stand for greater reliability and ease of management, but enables the machine to be cleaned in the quickest possible time.

Some of the major advantages of this Separator are automatic enclosed oil bath lubrication, self-balancing bowl of latest type, disc interior and seamless anti-splash supply can. These features, combined with its superior design and construction throughout enable the new “Ronaldson-Tippett” to skim cleaner, last longer, and cost less to work, thus increasing your returns and cut-ting your expenses.

For a quarter of a century the name “Ronaldson-Tippett” has been accepted throughout Australia as standing for the highest quality in farm machinery. This Separator bears our name as a guarantee that it combines all that is best in Separator design and construction.

A Challenge

It is easy to make extravagant claims for a Separator, whether they are justified or not. If there is the slightest doubt in your mind which Separator really is the most efficient, try this simple test.

Put a Ronaldson Tippett side by side with any other Separator of approximate capacity; take, say, 20 gallons of milk and run half through each machine; then run the skim milk from the other machine through the Ronaldson Tippett and vice versa.

The results will tell their own story and prove to you that the Ronaldson Tippett skim cleaner, is the easier to turn and more profitable to own.

Some Outstanding Features of the New Advanced Ronaldson Tippett

The Wonderful Self-Balancing Bowl

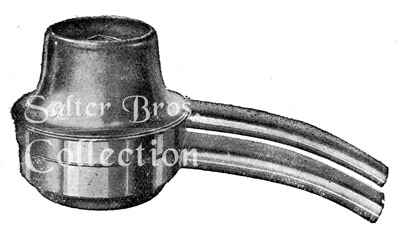

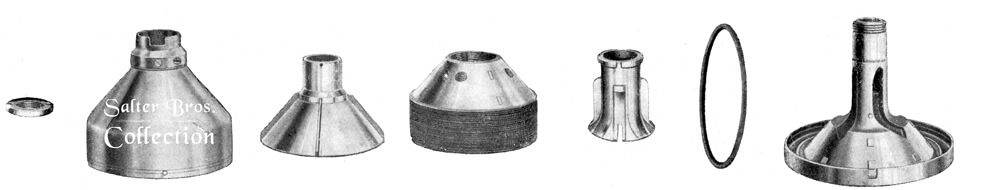

The Tinware

The Supply Can is made from special steel pressed out in one piece, free from any seams or rivets. It has a shoulder rim to prevent the milk from splashing over. The can rests on a removable bracket and is kept in position by three lugs.

The milk tap has a special port to allow a brush to be inserted for cleaning purposes without taking apart.

The Milk Float is oval shaped and fitted with guides to prevent it rotating in the regulating cup. No stem is used, and the float can be reversed, giving much longer life.

The Cream and Skim Milk Covers are so designed that frothing is absolutely eliminated. This Ronaldson Tippett feature does away with the necessity for drip pans. The spouts are long and heavy, and well tinned.

The Regulating Cup is pressed out of the solid, and has a shoulder rim which prevents the incoming milk from splashing over.

Cream and Skim Milk Covers

The Bowl in the new “Ronaldson-Tippett” has many exclusive and detailed features which are the cause of its wonderful skimming ability.

It is made of non-corrosive steel, smooth-sided without any corners or grooves to collect any foreign matter, and is easy to clean and always sweet.

It is so designed as to centre and balance itself when it attains separating speed, which causes it to run smoothly without vibration, and adds greatly to the efficiency and life of the machine—a factor of vital importance.

The skim milk has only one outlet, this being drilled on an angle which has a propelling action on the bowl.

When the skim milk is being forced out the deflecting shape of the outlet creates a turbine action which materially assists to propel the bowl.

This bowl runs on a pivoted point of scientific design, reducing friction to an almost immeasurable point. We cannot say too much for this particular feature of our machine.

The discs used in the bowl are unnumbered and can be inserted in any order.

This means that should a disc by some mischance be damaged a new one can be inserted by the owner with-out any difficulty whatever,

Bowl Parts

The Work Wheel Shaft is of the finest steel, cut from the solid, and has left and right spiral oiling grooves at eat end, which allows the lubricating oil to return to the centre of the shaft and back to the bath direc, and is not forced through bearings.

This preserves the lubricating oil, which can be used for a longer priod.

The Spindle is made from hardened steel, cut from the solid, machine turned and finished.

It has a special deep cut slot into the bowl, this being made in such a manner that if the bowl does not properly seat, the slightest movement of the handle will automatically permit the bowl to drop into the correct position.

The bearing point of the spindle is made from case-hardened steel, and rests on a similiar point in a machined socket tapped into the Separator frame.

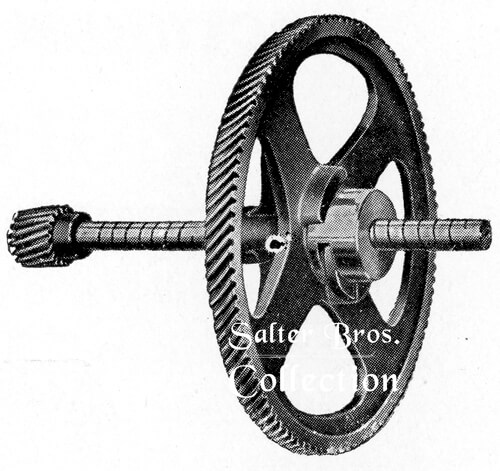

Worm Wheel and Ratchet

Spindle Top Bearing

Both points an be removed and replaced in a few seconds. The great simplicity of this design is a feature appreciated by all users of machinery. It not only reduces friction to almost vanishing point, but eliminates troubles which accrue from more complicated and intricate designs.

The Spindle Bearing consists of an accurately turned sleeve made from the finest steel and fitted with a removable phosphor bronze bush.

The bearing is held in position on its side by a specially constructed adjustable type spring which absorbs all shock and vibration, whereby spindle, gearing and bearing are given much longer life.

The Gearing

Great attention has been given by the makers of this latest Separator to various details in the design of the driving gear, resulting in increased efficiency and longer life.

The driving wheel and pinion. The driving wheel is securely keyed to its shaft, and has machine cut diagonal cogs, giving a smooth, noiseless running.

The driving shaft runs in heavily bushed taper seats cast solid with the frame.

The bushing has an oil groove milled out which lubricates the shaft, and has left and right handed spiral oiling grooves similar to hose on the worm wheel shafts.

The Worm Wheel is manufactured from phosphor bronze, and runs free on the shaft.

When driving the Separator the worm wheel is rotated by a ratchet consisting of a collar and pawl.

By this arrangement the driving wheel and shafts, as well as the worm wheel and shaft, stop revolving as soon as turning has ceased, which simply means that the only rotating parts are the bowl and spindle, thus giving greater life to the driving mechanism.

Driving Wheel and Pinion

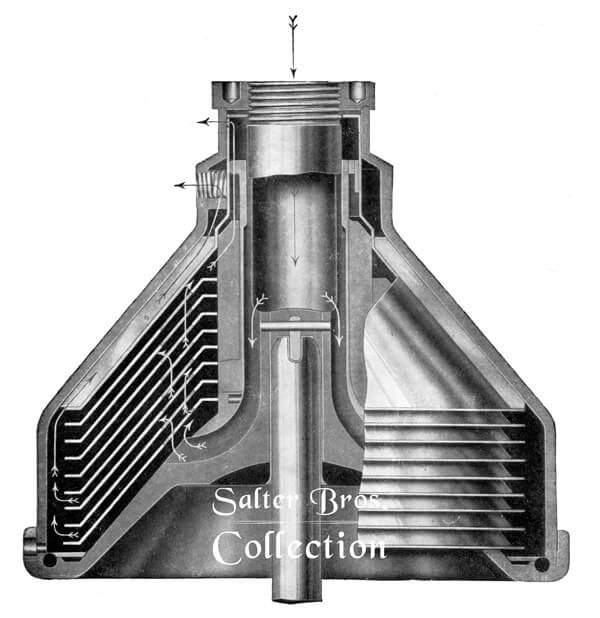

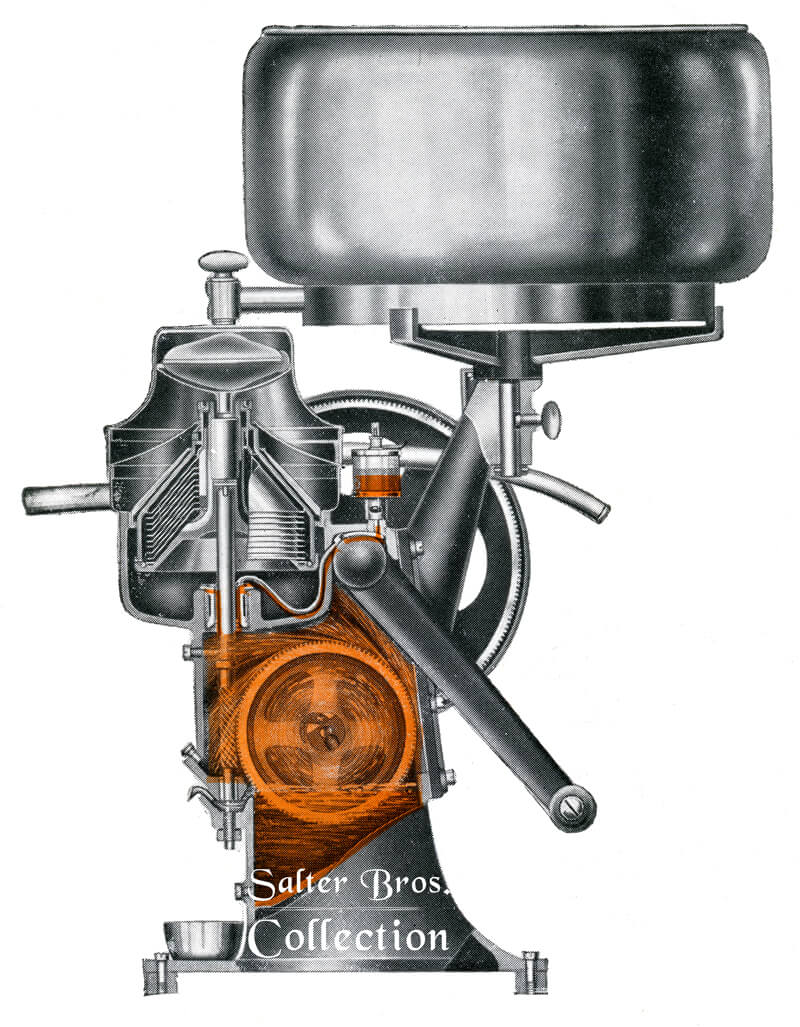

Automatic Lubrication

In the new advanced “Ronaldson-Tippett” Separator the lubrication is automatic, that is to say, that after filling the oil reservoir the machine oils itself.

The oil reservoir is situated in the base of the frame and provided with an over-flow so that the same level is maintained in the bath.

After the reservoir has been filled the machine will operate for three months with-out any further attention.

The lubrication is effected in the following manner:—On the machine being started the worm wheel, which is immersed to a depth of 4 in. in the oil bath, picks up the oil in the cogs and distributes it in a fine mist-like spray not only between the meshing gears, but throughout the length of every shaft and bearing of the machine.

This, with the exception of one sight feed lubricator, constitutes all the lubrication on the machine.

The sight feed lubricator, which oils the spindle neck bush is regulated by hand. All working parts being completely smothered in oil, friction is practically eliminated.

The perfect lubrication of the new “Ronaldson-Tippett” ensures long life, easiest possible running and the very minimum of duplicates.

Sectional View Showing The System of Automatic Lubrication

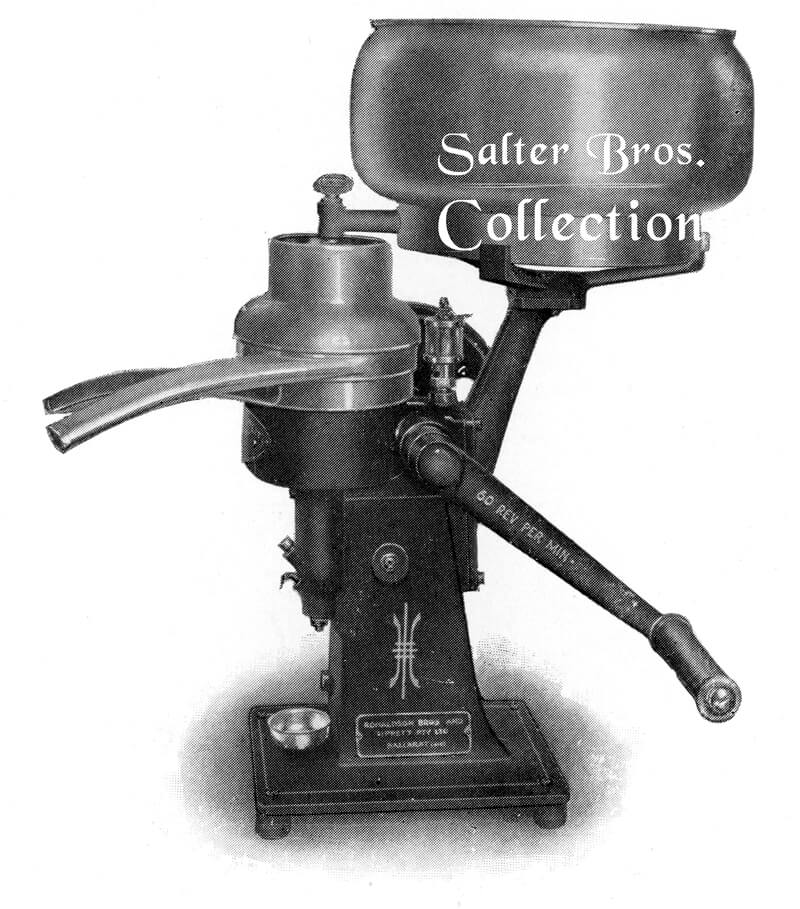

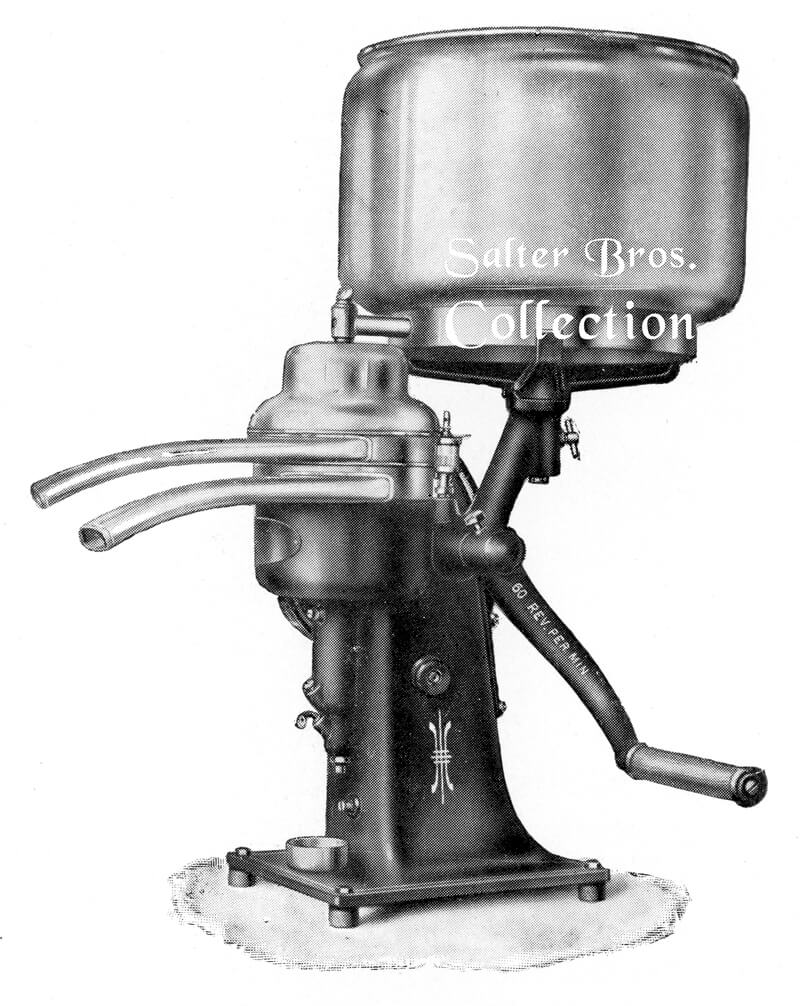

Ronaldson Tippett No. 30, Capacity 21 Gallons per hour

Ronaldson Tippett No. 31, Capacity 30 Gallons per hour

Ronaldson Tippett No. 32, Capacity 45 Gallons per hour

Ronaldson Tippett No. 34, Capacity 65 Gallons per hour

Ronaldson Tippett No. 35, Capacity 92 Gallons per hour

Ronaldson Tippett No. 36, Capacity 110 Gallons per hour

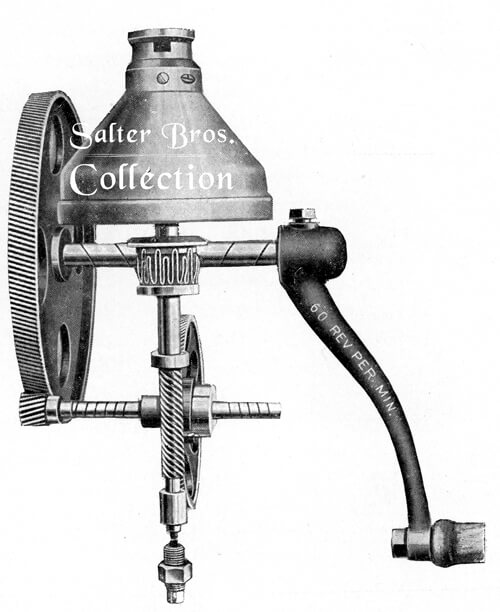

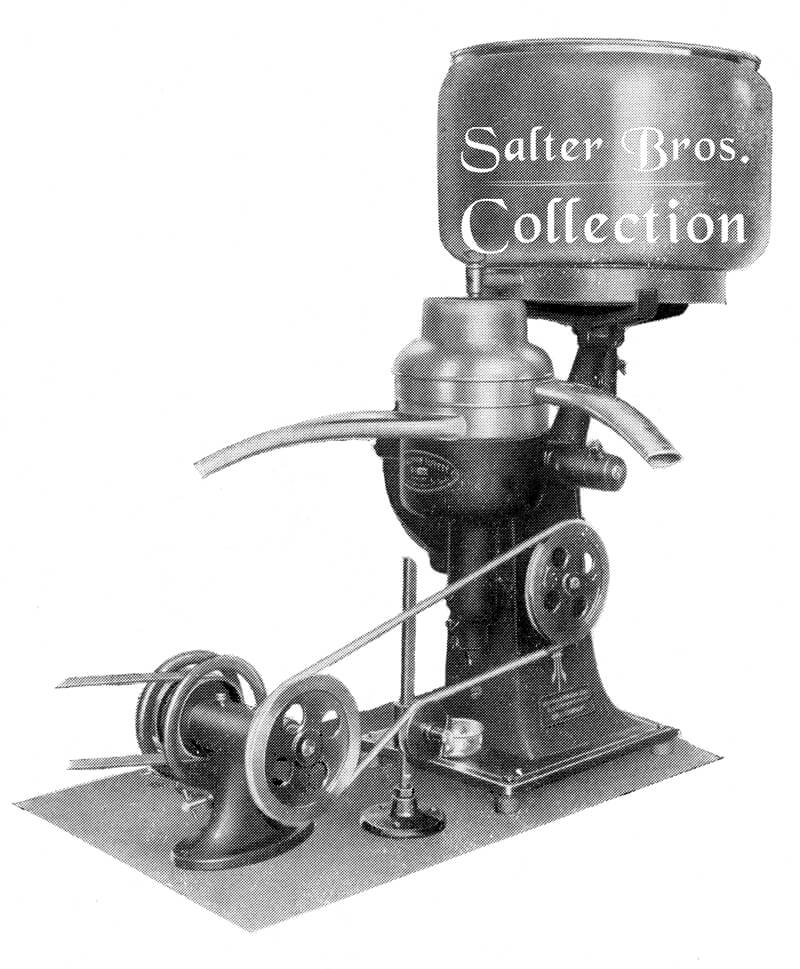

Power Drive

All Ronaldson Tippett Separators can be equipped with special attachments for electric drive or an intermediatefor direct connection with an engine, as shown above.

In the event of a power drive attachment being ordered with a standard Separator, a special plate will be necessary, and can be supplied at small extra cost.

In case the power should fail, the Separator may be driven by hand, as a crank and handle are always supplied with each separator.

Standard Models

All sizes of Ronaldson Tippett Separators can, at small extra cost, be supplied in the standard or high type as illustrated above.

The stand, which is of strong construction, supports the Separator rigidly at the height most convenient for turning and for filling the supply can.

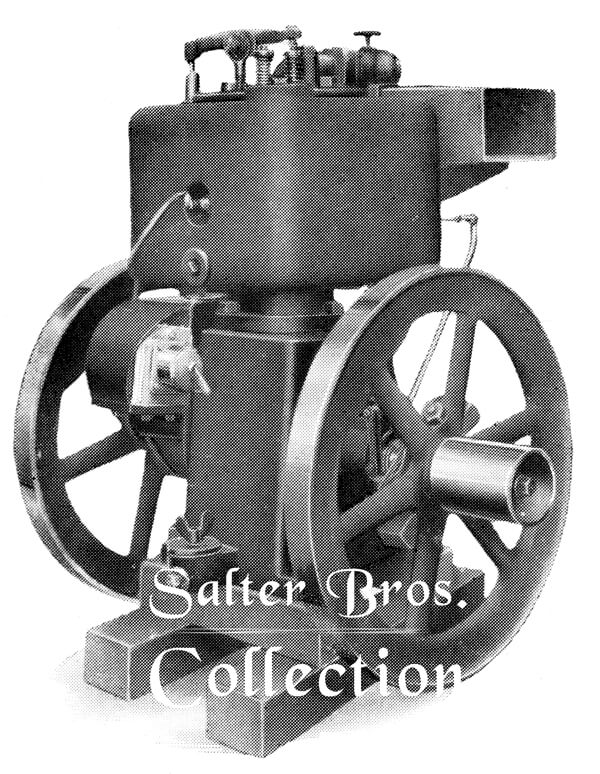

The Ideal Power for Separating

The New Ronaldson Tippett 1¾ H.P. Vertical Engine

The new Ronaldson-Tippett- 1 ¾h.p. Petrol Engine has been designed to meet the demand of the dairy farmer in particular—for a reliable high-grade power unit suitable for light farm work, at an attractive price.

It possesses the advantages of portability, compactness, light weight, complete protection from dust, dirt, etc., and capacity to run for long periods without oiling or attention.

Of the self-contained, hopper-cooled design, this Engine is of the vertical enclosed type.

It has an enclosed crank case with splash lubrication to the cylinder, piston, and all bearings.

In addition to many parts being case-hardened, semi-steel is used in the cylinder, piston and rings.

A gear driven, high tension, British magneto is used, which cuts out a number of intricate parts used on many small Engines. Overhead inlet and exhaust valves are embodied in the design.

All working parts are readily accessible, and generous size bearings are fitted.

The extreme simplicity of this Engine is one of its special features. This wonderful simplicity combined with first class materials and workmanship, ensures exceptional reliability and even running.

Backing this high grade power unit is the service of the largest and oldest Engine Manufacturers in Australia, noted for their straight forward business methods and lasting practical interest in every Engine or Machine sold.

In addition to driving Separators, this Engine is particularly adapted for driving 8in., 2 knife chaff cutters, small Saw benches, Pump Jacks, Elevators, concrete Mixers, etc.

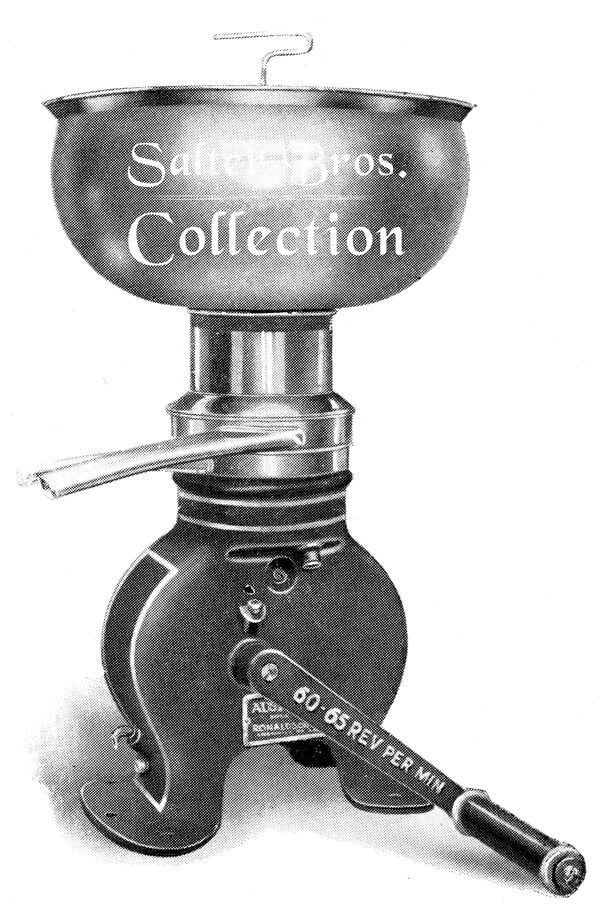

The New Austral Separators

In order to cater for even the man who milks one or two cows we supply our Separators in 9 and 13 gal sizes.

These machines are sligtly different in frame design and in the shape of the tinware. They are sold under the registered name “Austral.”

These two Separators combined all the features of the biggest machines, and are made in the same factory as the new, advanced “Ronaldson-Tippett.”

The 13-gal. “Austral is automatically lubricated – an unusual feature in a machine of this size and type. The 9-gal. size has three point lubrication – the acme of simplicity.

Austral No. 10, Capacity, 9 Galls. per hour.

Austral No. 11, Capacity 13 Galls. per hour.