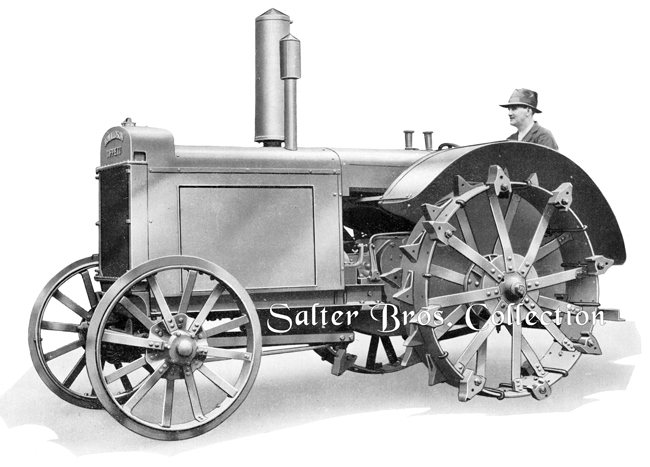

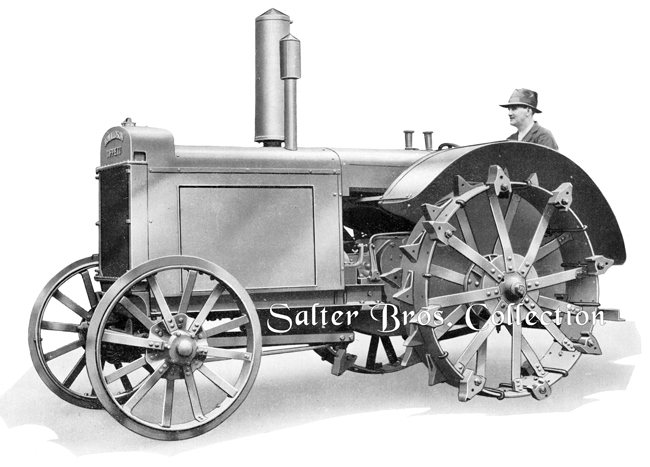

Ronaldson Tippett Super Drive Tractor

A Gild-Edged Investment

Buy the best – because it is cheaper in the long run.

It is not a question of whether you can afford the high-grade “Ronaldson-Tippett,” but whether you can afford to be without it.

It is not the price you pay, but the years of service you get which determines a tractor’s cost. When you buy from a reputable experienced makers in your your own country, you have a definite assurance of sound engineering service for all time.

Every feature in the “Ronaldson-Tippett” has been considered to ensure the longest life with the lowest cost for duplicates – the greatest power with the lowest consumption of fuel and lubricating oil – the least weight with the greatest strength and traction.

Viewed from every possible angle – advanced design, quality construction, economic working, and better service – the “Ronaldson-Tippett” is the right Tractor to purchase.

It has proved itself beyond all doubt to be a gilt-edged investment.

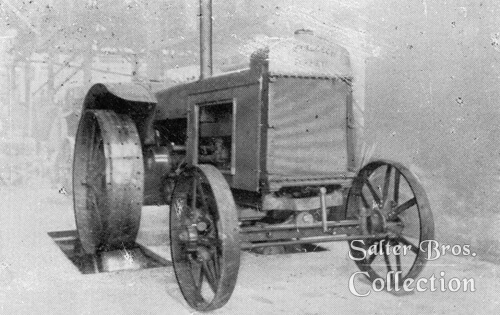

20 – 36 H.P. Ronaldson-Tippett Super-Drive Tractor

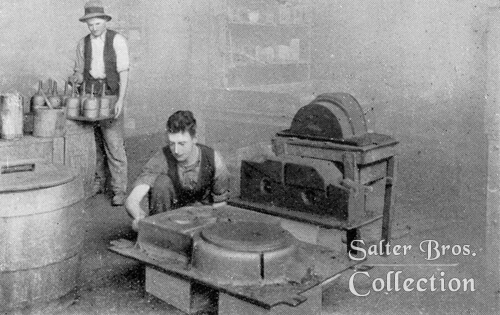

Moulding a Tractor Transmission Case

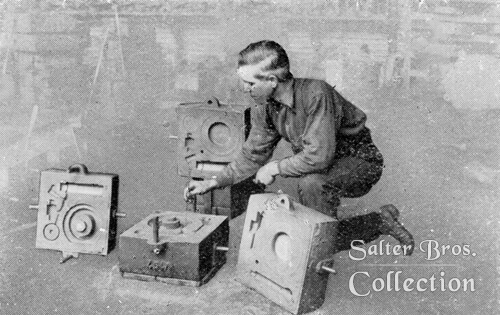

Making Cores for Transmission Case

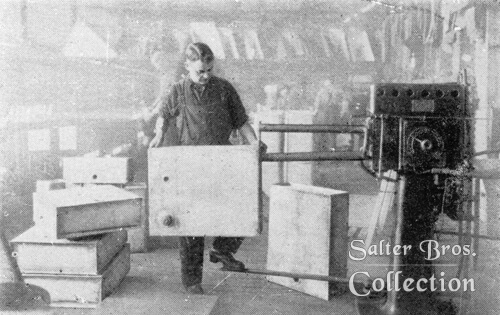

Plate Moulding Small Parts of the Tractor

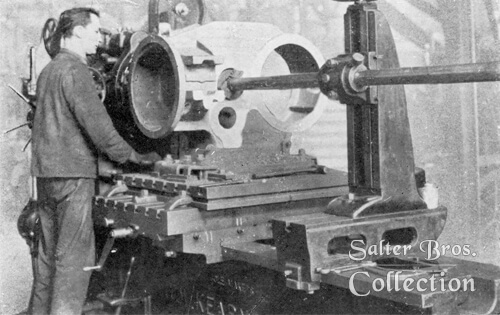

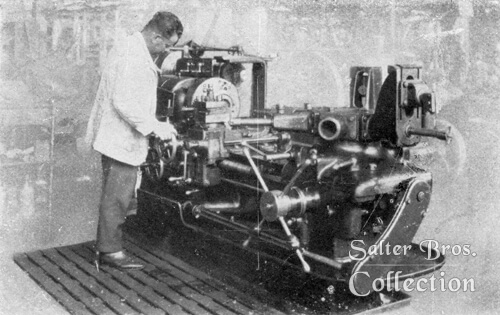

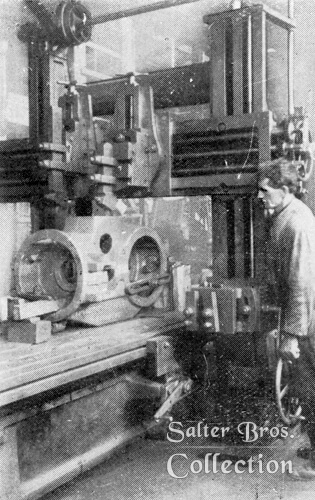

Machining a Tractor Transmission Case

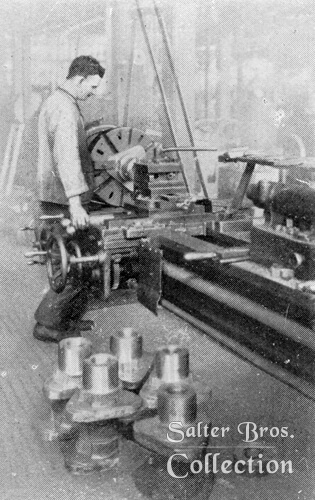

Machining Cases for Roller Bearings

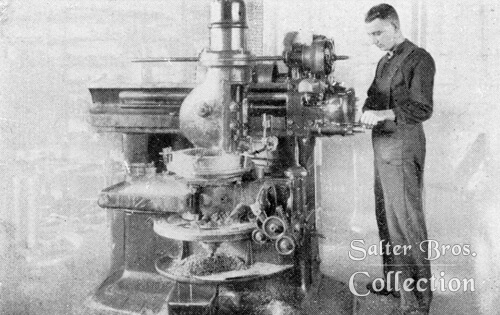

Boring out Back Wheel Hubs on a Turret Lathe

Fitting the Radiator Cores into the Cast Frames

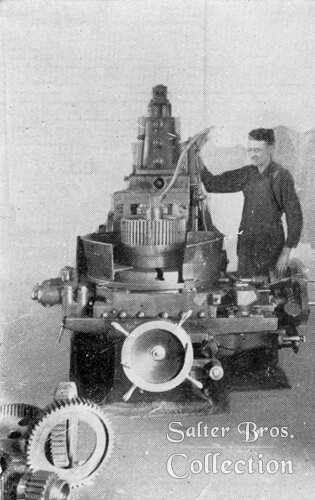

Cutting the Internal Gears of the Super-Drive

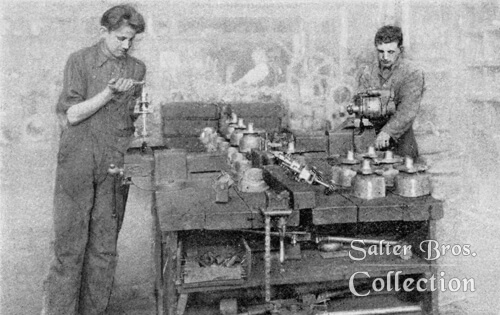

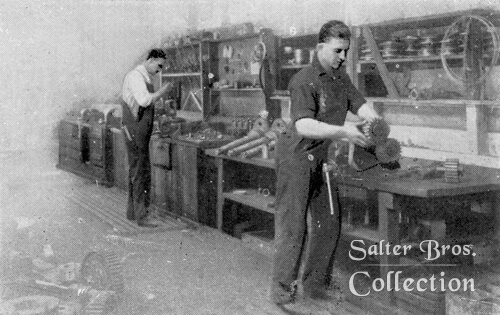

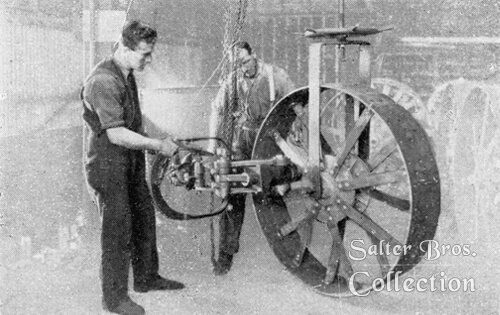

Fitting Governors together after Machining

Fitting up the Super-Drive Gears

Cutting Spur Gears

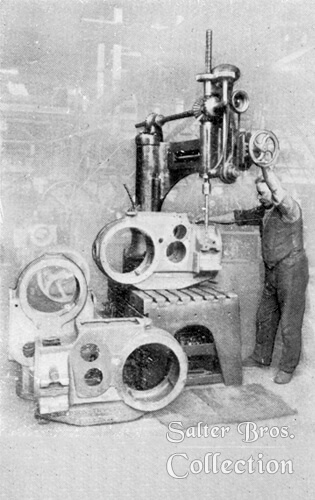

Drilling a Transmision Case

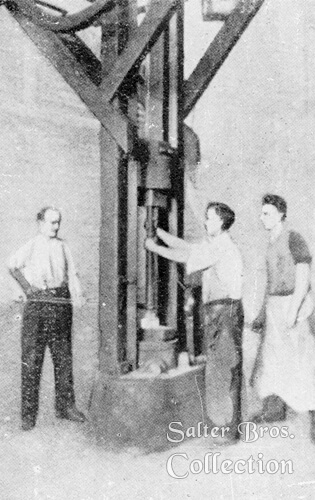

Forging a Tractor Draw-Bar under the big Power Hammer

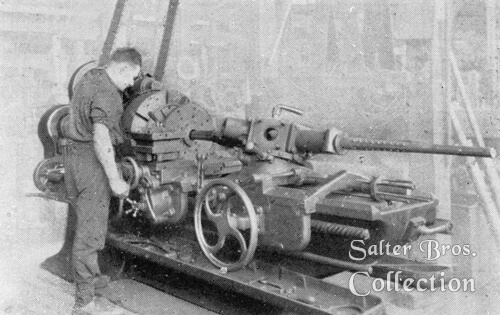

Planing the Transmission Case

Fitting up Clutches

Machining Back Axle Spiders

Electric Spot Welding Fuel Tanks

Swinging the Differential into the Transmission Case and Placing the Treble Gears into Position

Riveting Travelling Wheels with Pneumatic Riveter

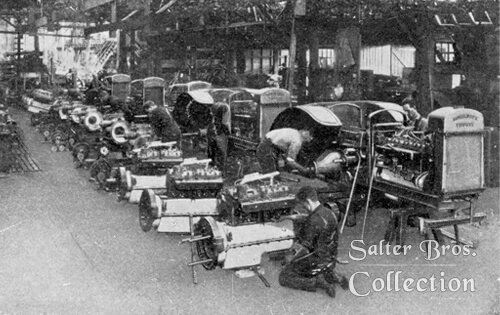

Final Assembly Line

Fitting Covers and Bonnets to Tractors

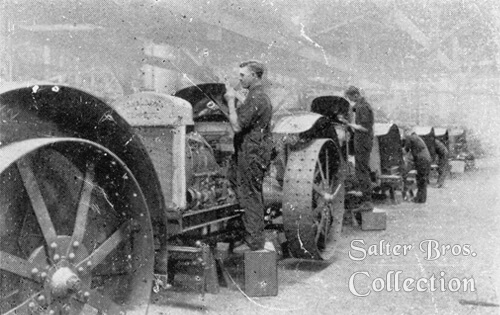

Running a Tractor in on Rollers

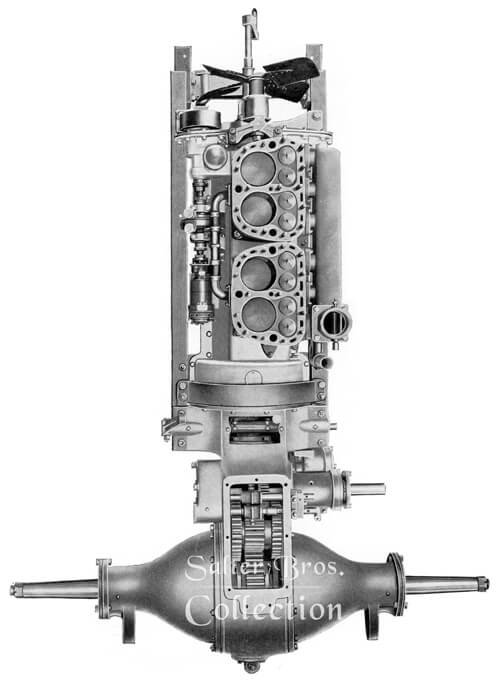

Top View of Engine and Transmission Gear

This view gives some idea of the clean cut, well balanced design of vital parts of the Tractor.

Simplicity and a get-at-ability are of great importance with all machinery for the man on the land, and in this respect the “Ronaldson-Tippett” Super-Drive leaves nothing to be desired.

The Engine is shown with the cylinder heads removed.

The tramsission case cover has also been taken off to partly show the gearing.

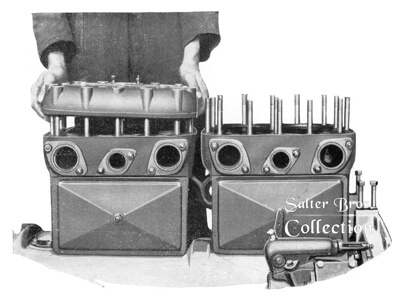

The New 20 – 36 h.p. “Ronaldson-Tippett” Super-Drive Tractor

A triumph of Australian Engineering embodying many features ensuring greater reliability, longer life and lower costs under Australian conditions.

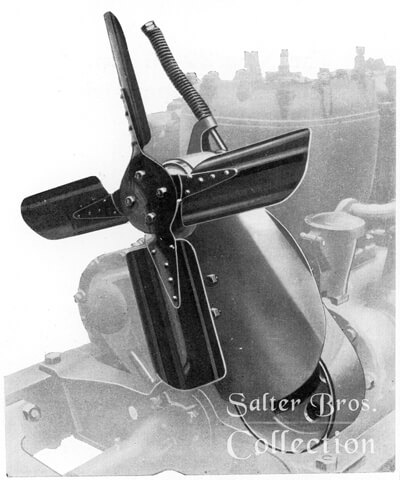

The Fan

This illustration shows the extra large fan and the big three inch fan belt. The fan runs on Timpken tapered roller bearings, which are adjustable.

Behind the fan will be seen the sheet steal guard protecting the belt from hot fan blast and sand.

Projecting above the belt is the improved design spring tension belt tightener.

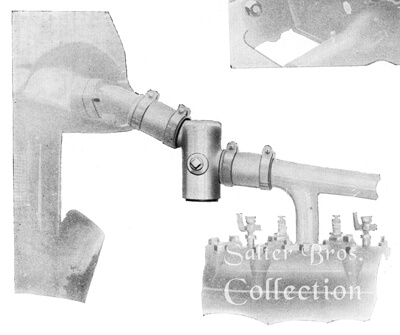

The Thermostat

This illustration on the left is of the Thermostat.

This fitting automatically regulates the water temperature and is adjustable to suit weather and load conditions.

In addition it reduces dilution of the lubricant oil by bringing the temperature of the cylinders up to required degree in a very short time, and keeping it there.

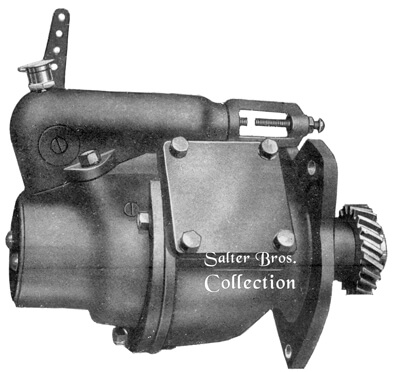

Cooling System

Special consideration has been given to the cooling system to suit Australian hot summer conditions. With the “Ronaldson-Tippett” it is not necessary to cart quantities of water, as the tractor, under average hot summer conditions will not use more than about a gallon of water a day.

The cooling system is of the forced circulation type, the water being circulated by a simple type of centrifugal pump. The pump – illustrated to the left is carried in brackets on the magneto shaft. A special flexible coupling is provided to drive the same.

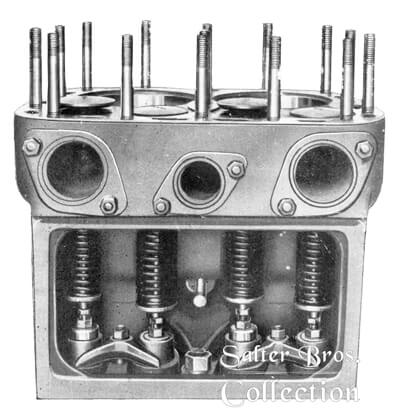

Valves and Tappets

In the photo at the right the cover has been removed from one of the cylinders, exposing the valves, tappets and springs.

The valves are forged in one piece. The inlet valves are of chrome nickel street, whilst the exhaust valves are made from tungsten steel.

These steels have been specially selected as being most adapted to each valve’s particular function.

The springs are large and long to prevent crystallisation and breaking.

Tappets are of the roller type, with all wearing surfaces hardened and ground.

The tappet guides, which are extra long are replaceable.

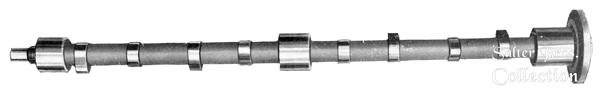

The Camshaft

The camshaft, shown to the right is a solid streel forging, with cams and driving flanges forged integral. All bearings and cam faces are hardened and accurately ground. Note large bearings.

The Bearings

The illustration to the right shows complete set of British “Hoffmann” Roller Bearings used in our transmission case.

These bearings are the world’s highest grade production, and have a load carrying capacity 50 per cent. greater than roller bearings.

They have been installed in our Tractor only at considerable extra cost. During the twelve years we have used these bearings we can definitely say that we have not supplied more than one dozen bearings are duplicates.

Detachable Cylinder Heads

Owing to the fact that the cylinders are cast in pairs the cylinder heads can be removed with the greatest ease. Separate cylinders in pairs have many other advantages as enumerated in succeeding content.

Nickel iron is now used in the cylinder blocks and give smuch more wear than metals generally used.

The join between the cylinder head and the cylinder is made with a copper asbestos gasket.

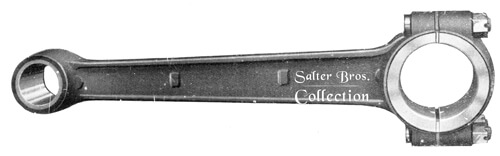

Piston and Connecting Rod

The pistons are made of special quality metal, carefully machined and ground. They are fitted with two compression rings and one oil ring. The gudgeon pins are held in the bosses by Woodruff keys and spring wire lockrings are fitted in the ends of the piston bosses to prevent end motion of the pins.

The connecting rods are “I” section steel drop forgings, thus giving the maximum strength with light weight. The big-end bearings are of high grade babbit metal, cast under 600 lbs. pressure. The gudgeon bushes are of phosphor bronze of the highest quality.

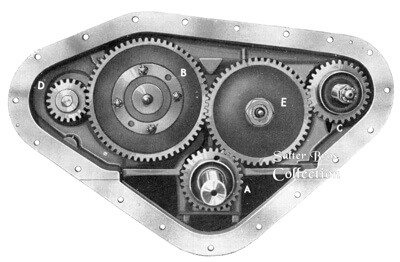

Timing Gears

The wide face timing gears are of the single helical type, preventing all back lash, and giving longer wear.

In the illustration the five gears are identified as follows:

A. Crankshaft gear.

B. Camshaft gear.

C. Magneto and pump drive gear.

D. Governor drive gear.

E. Idler gear

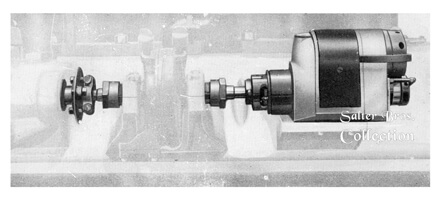

Bosch Magneto and Flexible Coupling

As shown by this phone., ignition is by means of a genuine “Bosch” high tension magneto with impulse coupling. We use the “Bosch” magneto as standard equipment, because of its wonderful reliability and long life. It is waterproof, and has only one oiling point

We could save money by using a cheaper magneto, but it has always been our policy to use the best, regardless of cost, in an earnest endeavour to give our clients a tractor with the highest possible efficiency. A dust proof cover is now fitted over impulse coupling.

At the left of the photo will be seen the specially designed steel plate flexible coupling.

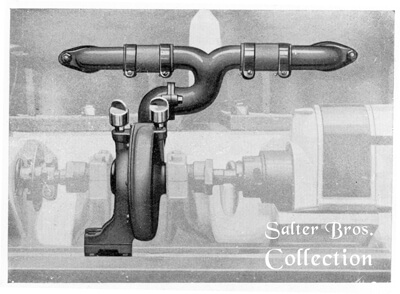

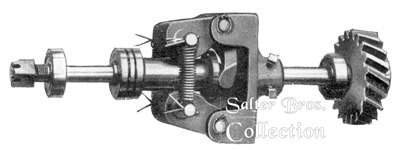

The Governor

The photo to the right shows: At the top, the governor mechanism withdrawn from the case; and below the complete governor in housing.

Of the fly-ball type, this governor is very sensitie and is easily adjusted.

The main spindle is carried on two radial ball bearings of ample size.

These are shown at each end of the shaft in the top photo.

A thrust ball bearing is provided to eliminate wear between the revolving portion of the governor and the stationary fork, which operates the lever.

This is shown in towards the centre of the top photo.

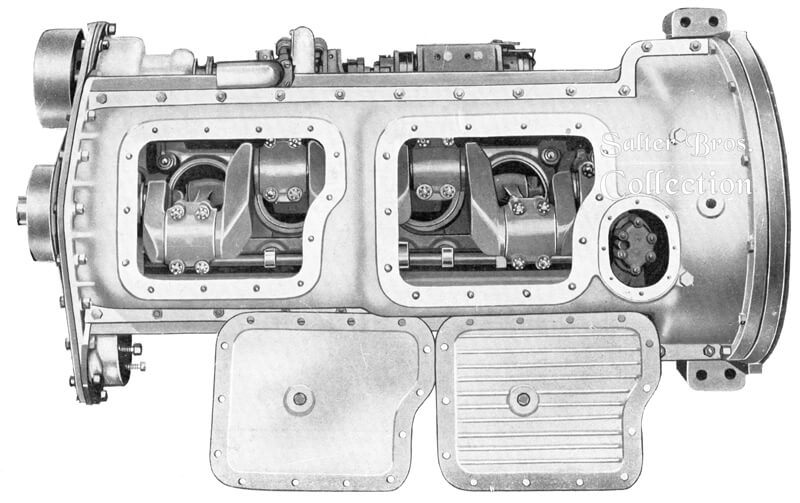

View of Engine Showing Inspection Plates Removed

You will see from the above photo that plates are of sufficiently large dimensions to actually permit a man to get at the bearings.

This stands out favourably in contrast with the small port holes of useless size on many designs. At the right hand side of the illustration is also shown a plate removed, which allows for the inspection of the oil pump.

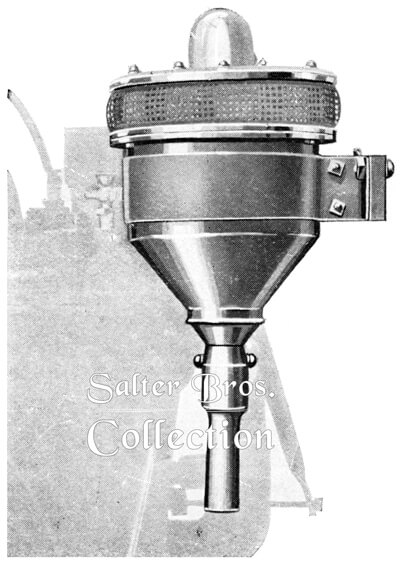

The Air Cleaner

An improved air cleaner is fitted, which works on the centrifugal principle, ensuring the greatest efficiency.

An important feature of this cleaner is that it requires cleaning or attention only at long intervals.