Ronaldson Bros. & Tippett – Type N

Type N Petrol Engine

According to Ronaldson Bros. & Tippett records, the first Type N rolled off the production line on 10th of August 1932.

Starting with sizes 1.25 H.P. and 2.5 H.P.

The first serial number of a Type N produced was 8604.

Are all Type N engines the same?

The short answer to this question is no, over the years Ronaldson Bros. & Tippett refined their design of the Type N and made changes.

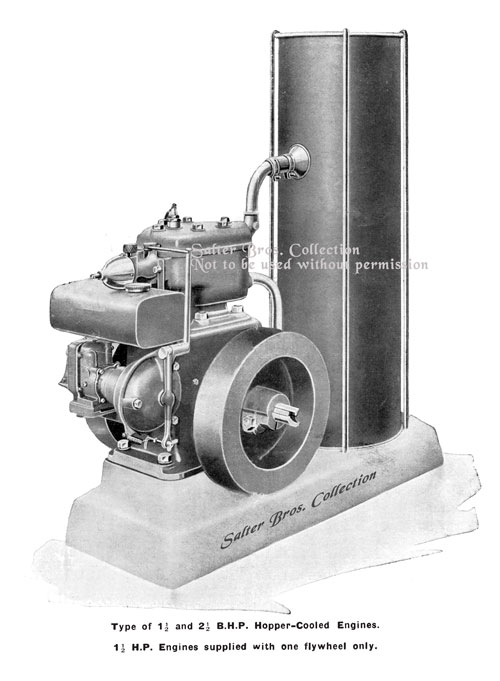

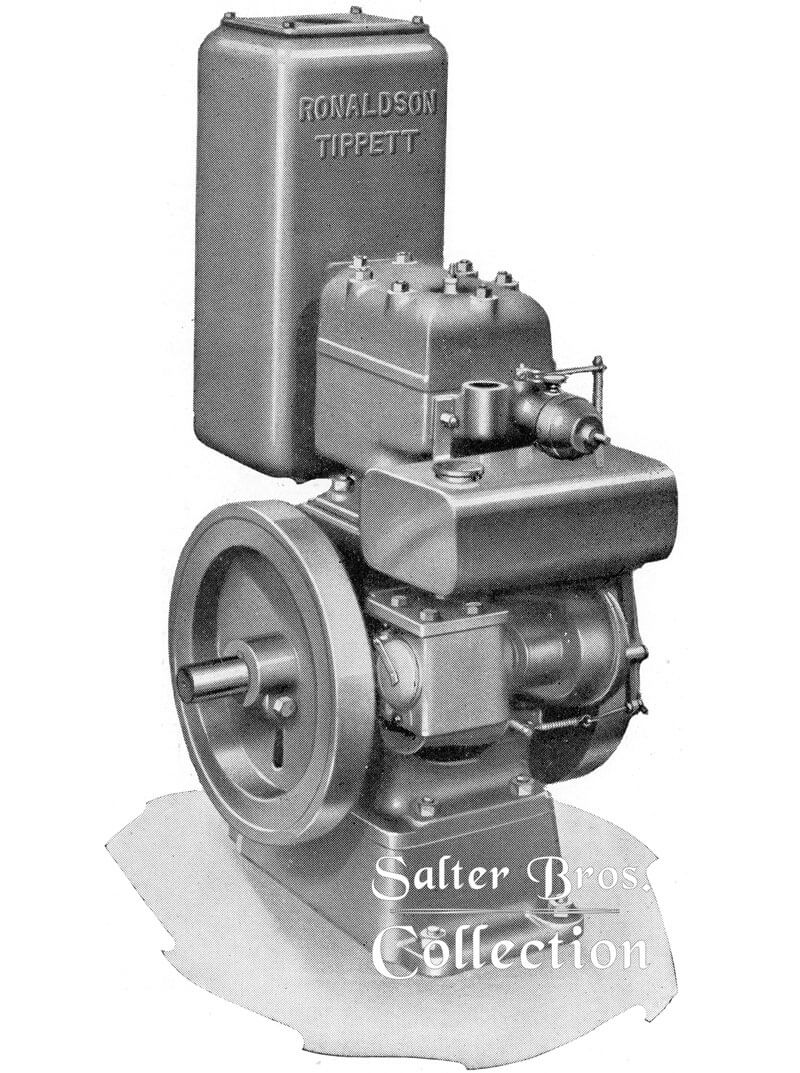

Type N – 1.5 H.P.

Type N – 2 H.P.

Type N – 3 H.P.

Type N – 4 H.P.

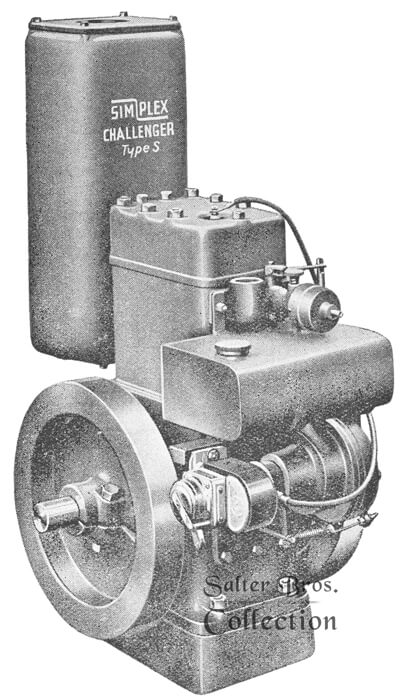

Baltic Simplex

These engines were built by Ronaldson Tippett but sold under the Baltic Simplex name as Simplex Challenger engines.

They were available in 2 H.P. and 3 H.P.

More information will follow on Baltic Simplex Machinery Co. LTD.

475 – 477 Flinders Lane, Melbourne, Victoria.

608 – 614 Harris Street, Sydney, New South Wales.

179 – 181 Mary Street, Brisbane, Queensland.

Type S – 2 & 3 H.P.

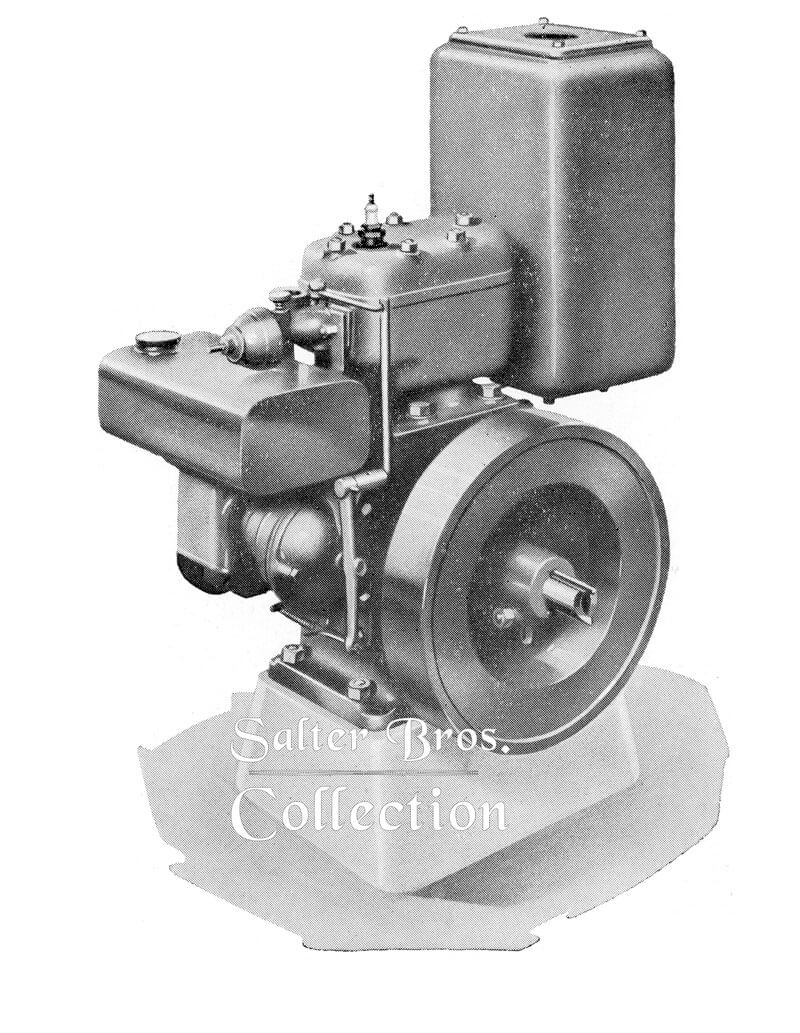

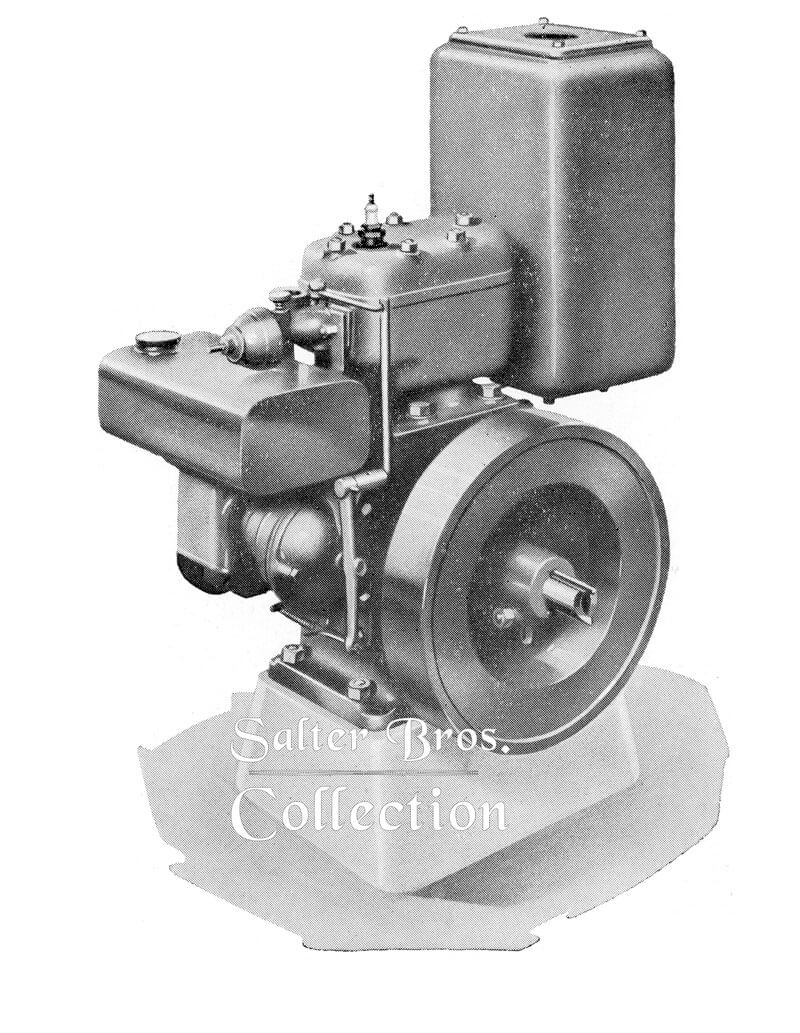

Ronaldson Tippett Type N, 3 H.P.

Petrol Kerosene Engine

Your Best Power Buy!

Round-the-Clock Performance. . .

When it’s a long, continuous run you are wanting, this is the engine you’ll want to do it! Just top up the fuel tank, check oil and water, and you’re set for truly round-the-clock operation . . . and you can DEPEND on it!

Low Operating Costs . . .

Economy in fuel usage is assured with the patented Ronaldson Tippett Petrol Kerosene attachment.

A fool-proof start on petrol, then the engine automatically switches over to low-priced power kerosene.

Its a certain start . . . . you can DEPEND on it!

Exceptionally Long Life . . .

Quality materials, processed by skilled craftsmen, ensure maximum return for your investment in long, trouble-free life.

When long-running brings need for renewals of wearing parts, there’s no waiting for imported parts in short supply.

Ronaldson Tippett parts are obtainable at once, anywhere in Australia.

Many hundreds of original Ronaldson Tippett engines are still giving satisfaction to their owners.

These men invested well and wisely . . . You can do the same!

Buy Ronaldson Tippett . . . you can DEPEND on it!

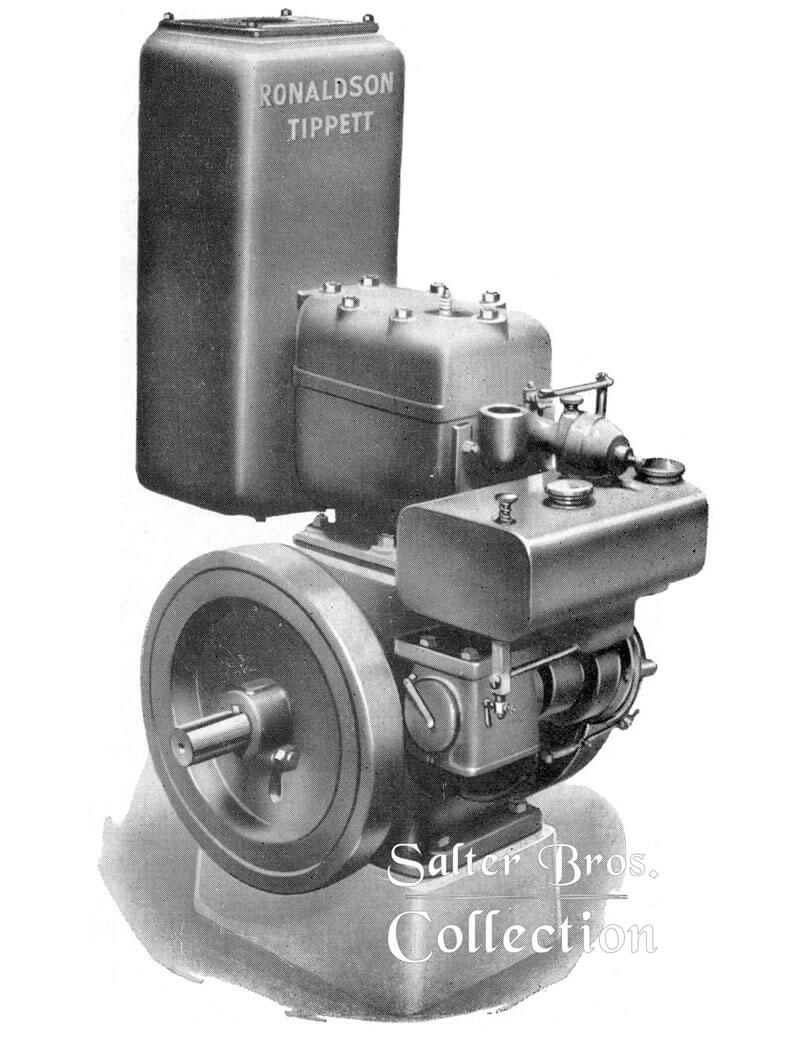

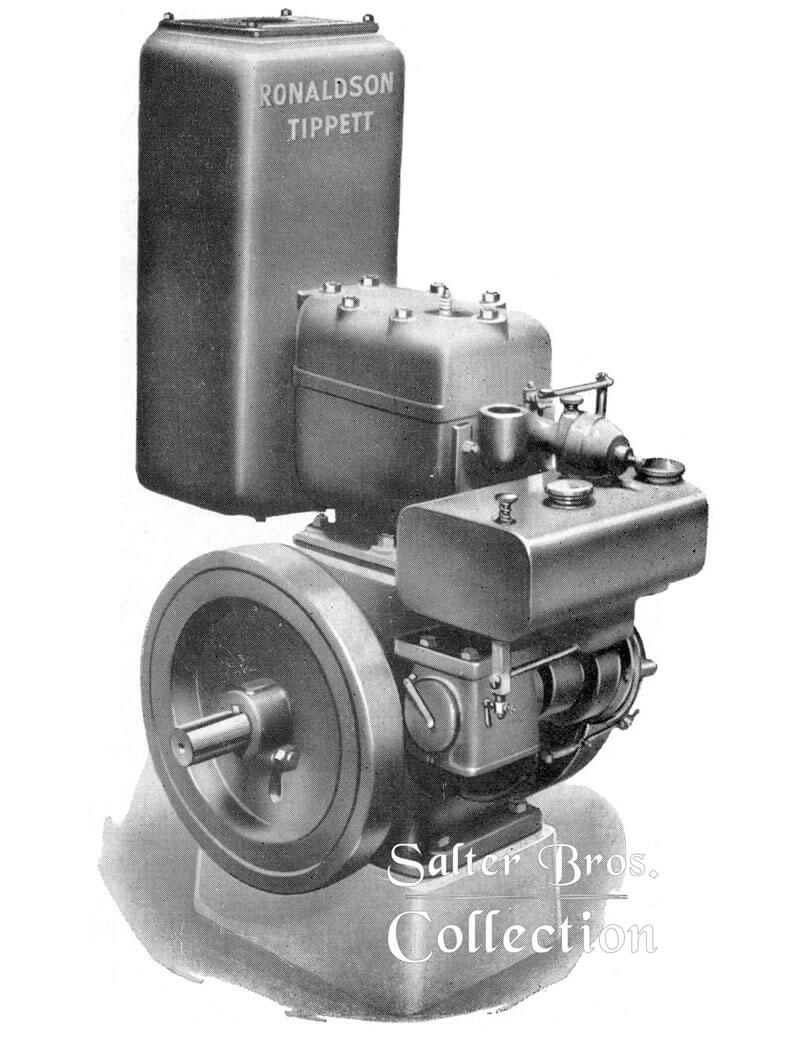

Ronaldson Tippett Type N, 4 H.P.

Hopper Cooled, Vertical, Petrol Engine

Some of the Features which makes the

Ronaldson Tippett Engine

your best investment!

- Extremely simple in construction.

- Easy to start and manage.

- Totally enclosed and sealed against dust and grit.

- Although totally enclosed these Engines are very accessible.

- Carburettor of extremely simple design. No floats or juggling needle valves to wear out or get out of adjustment.

- Cylinder Block separate from Bed and Head, enabling quick replacement at very low cost.

- Balanced Crankshaft ensures sweet, vibrationless running.

- Sealed against oil leaks by Patent Seals.

- Automatic lubrication throughout. One oiling point only.

- All castings heat-treated.

- Alloy cast iron Cylinder and Piston

- Wonderfully sensitive governing under all conditions.

- Best quality high-tension Magneto.

- Silent running, compact and splendidly finished.

Service . . . Always Available!

When you invest in a Ronaldson Tippett Engine, you become one of the great family of R-T owners . . . men all over Australia who know that we give live, practical, interested service at all times.

You can always secure spare parts for Ronaldson Tippett Engines . . . anywhere in Australia.

No waiting for an out of stock imported part.

Ronaldson Tippett Engines are made entirely in Australia, by makers who for fifty years past have concentrated on making the best Engine for Australian conditions.

Keep your money in Australia and get more for it in better engines and permanent service!

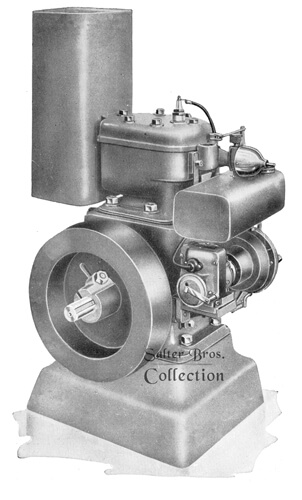

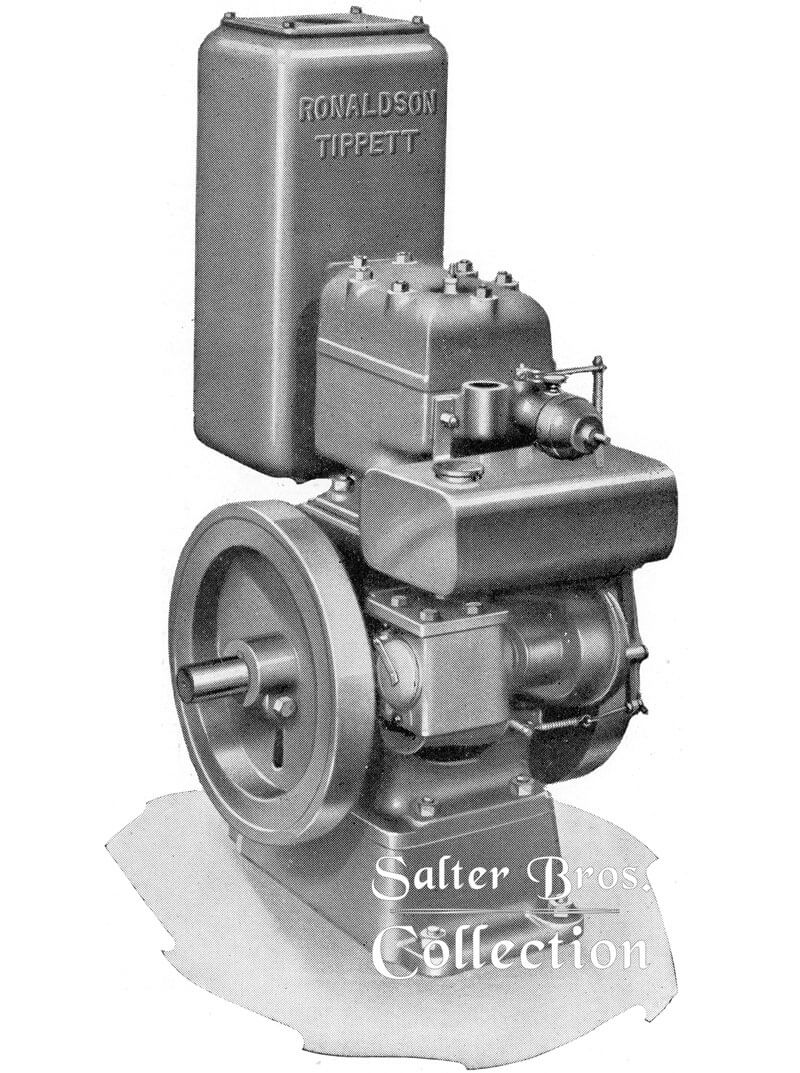

Ronaldson Tippett Type N, 2 H.P.

Hopper Cooled, Vertical, Petrol Engine

Reasons WHY Ronaldson Tippett Engines Lead for Quality, Reliability, Long Life and Efficency under the most Arduous Conditions!

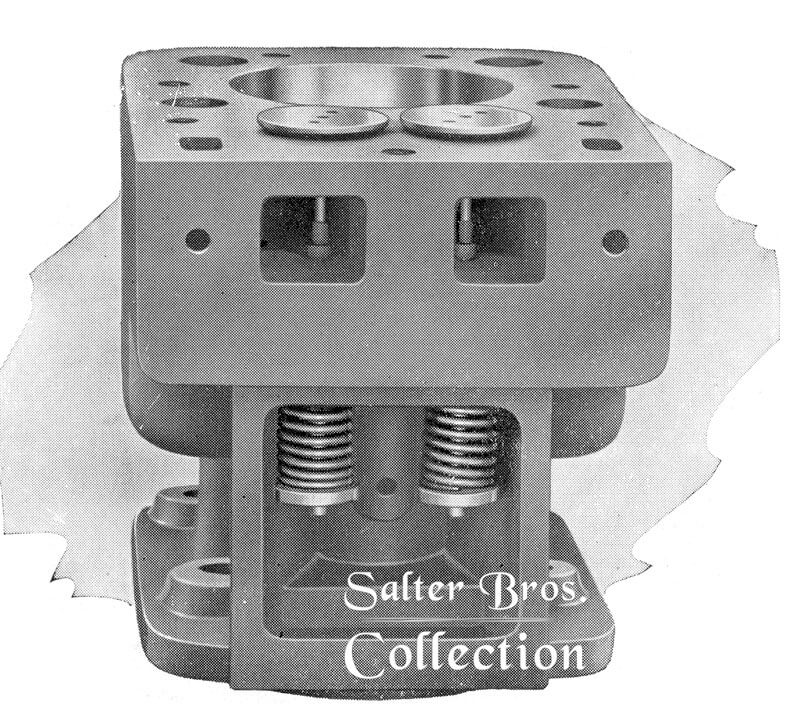

Cylinder Block

On of the many features of the Engine is the specially designed Cylinder Block.

Cast separately from the crankcase and cylinder head, it can be easily replaced when rendered necessary after many years of arduous work, or by negligence.

Such a replacement costs only a few pounds and can be done by anyone in about half an hour . . . no costly re-bore or weeks of waiting.

Cylinder after machining, is honed true to one half-thousandth of an inch, giving an unusually hard and glass-smooth surface.

Silchrome steel valves are used, ensuring very little grinding after many years of service.

Tappets and Valve stems work in an oil sprayed, dust-proof chamber, cover of which is removed in the photo on the left.

Heat-Treated Castings

All castings are placed in an oil-fired furnace where they are subjected to special heat-treatment for twelve hours. This frees them of all stresses.

No further distortion can take place after machining, as often happens with non-heat-treated castings.

Distortions mean undie pressure on wearing parts with shorter life and lower efficiency.

Ronaldson Tippett engines are, we believe, the only power units produced with all castings heat-treated

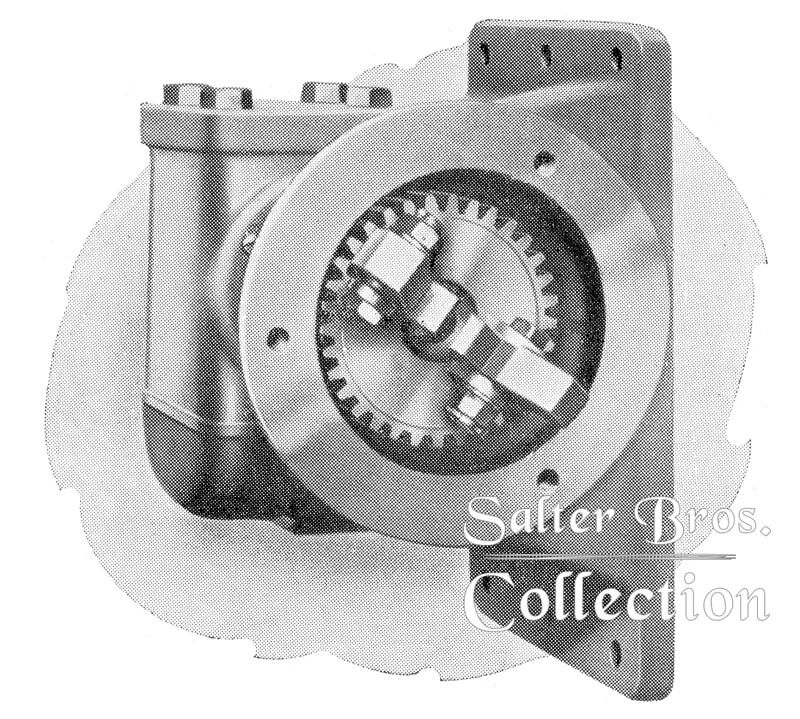

Governor

The Governor is carried on the Pinion driving the Magneto and is of the very simplest design.

Governor weights are made from special steel, case-hardened to eliminate wear.

Governor is totally enclosed, running in an oil bath, but can quickly got at by removing a small place.

This Governor is remarkly quick and efficient in its action.

Constant speeds are definitely assured under any conditions whatever – a highly important feature for all work.

Speed can be varied by regulating a thumb screw while engine is running.

•

An Investment that will Pay lifetime dividends!

•

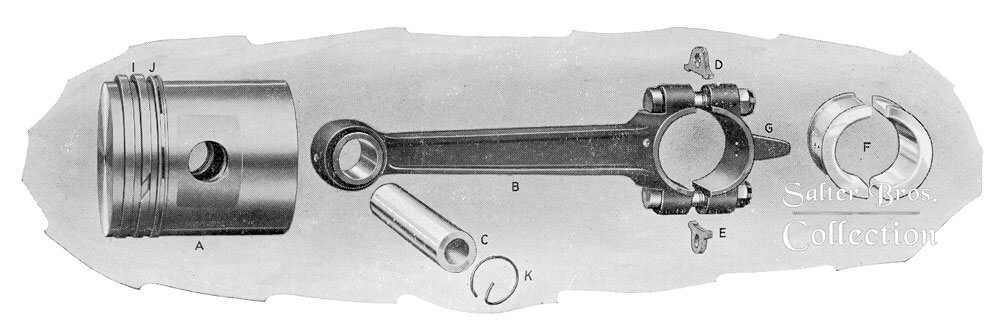

Piston and Connecting Rod

The Piston (A) is in special alloy cast iron, finished to a half-thousandth of an inch.

The three rings – two compresion (I) and one oil (J) – are of the latest design, ensuring perfect compression and long life.

The Connecting Rod (B) is drop-forged in special high-tensile steel, heat-treated. Gudgeon Bush is in phosphor bronze.

Gudgeon Pin (C) is of floating type, case=hardened and ground true to a half thousandth of an inch.

Big-End Bearings (F) are die-cast, giving long life with a minimum of attention.

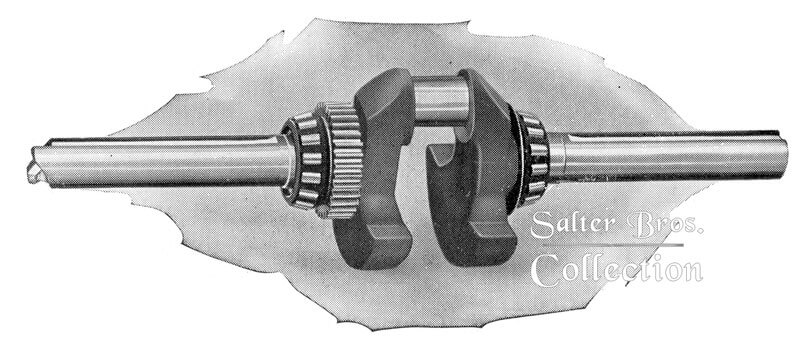

Main Bearings

The use of Tapered Roller-Bearings is an important advance in design, enabling a very compact engine to be built, and ensuring the elimination of all Main Bearing Troubles.

Highest efficiency is assured because friction is reduced to almost nil, and crankshaft wear at the Main Bearings is avoided.

Lubrication

Working parts are not only totally enclosed, protecting them from dust and grit, but they operate in an oil or oil-vapour bath.

Lubrication is entirely automatic throughout, with only one oiling point.

Every working part on the engine is lubricated efficiently and positively.

Complete reliability and the longest possible life is thus assured even under the worst working conditions.

Oil Seals

Special Oil Seals, fitted to the crankshaft, prevent oil leaks and oil throwing off from the flywheel.

This is but one of the refinements which place the Ronaldson Tippett engine definitely in the front rank of quality engines.

Camshaft

Cams are ground on a special profiling machine ensuring true timing and high engine efficiency.

All Gears are, of course, machine-cut and as they run in the constant oil bath, long life and silent operation are assured.

The Camshaft Gear is in phosphor bronze, and both Pinions are in special steel.

Crankshaft

The drop-forged Crankshaft is made of the highest-quality steel, not only ensuring the greatest strength, but the longest wearing life.

After heat-treating it is machined and finally ground true to a half-thousandth of an inch.

Balance weights are integral with the web, giving wonderfully sweet, vibrationless running, with consequent long life to the wear parts of the Engine.

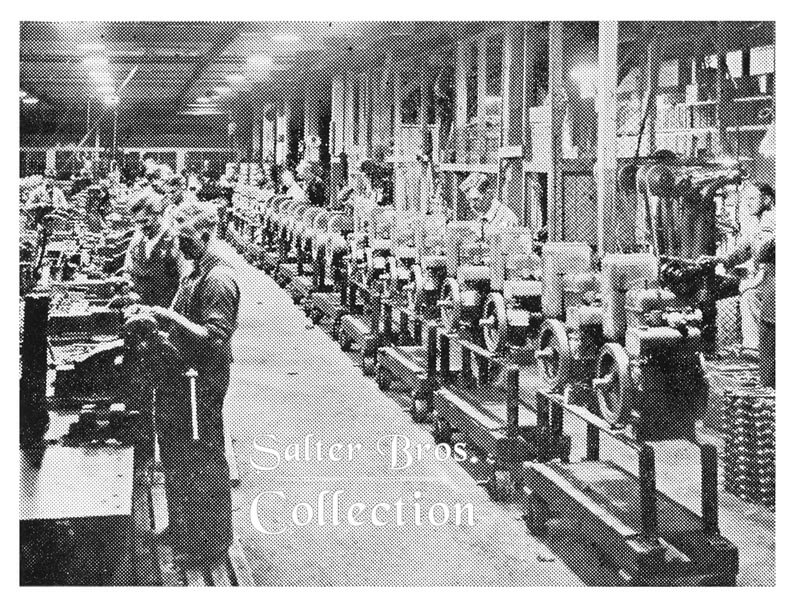

Modern Assembly Methods

Ensure a Precision-Built Product!

This is our Petrol Engine Bay, where this type of Engine is built under standardised progressive assembly methods.

Rigid inspection at every stage of the manufacture of the Engine assures that reliability for which Ronaldson Tippett engines are famed throught the land.

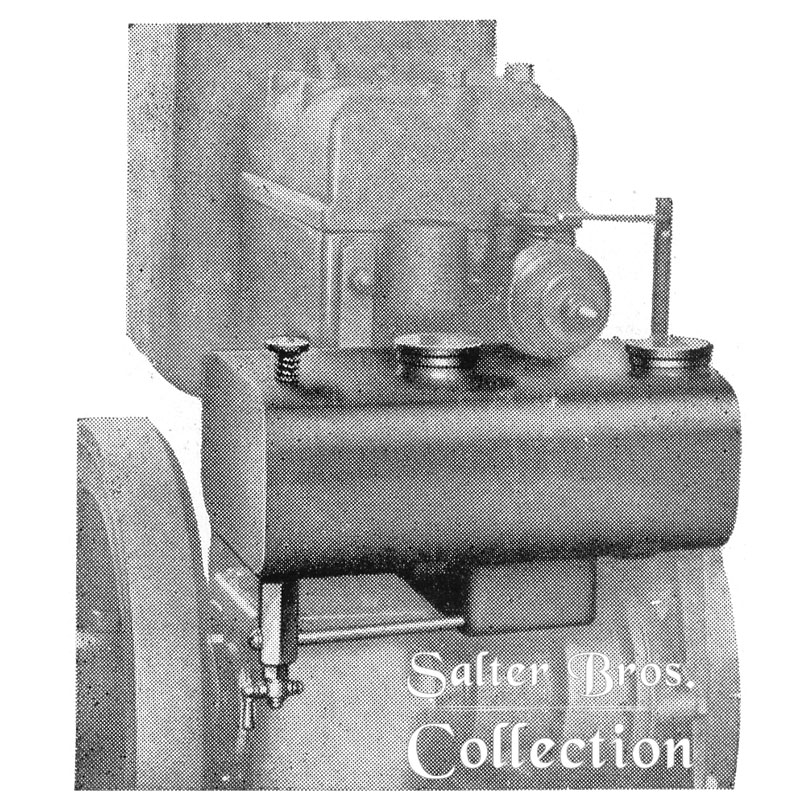

Amazing Fuel Economy!

Patented Petrol-Kerosene Attachment Ensures Efficient Running on Power Kerosene.

This illustrates the special fuel tank with which the Petrol-Kerosene Engines are equipped.

The main container is for power kerosene, the small compartment beneath holds enough starting petrol to ensure a sufficiently hot engine for changing over to kerosene.

Some of its advantages are:

1. Extremely simplicity – change over to kerosene entirely automatic.

2. Once engine is set in motion there is no necessity to make any further adjustments.

3. The design (which is a Ronaldson Tippett Patent) provides splendid combustion – much better than is the case with other Kerosene Engines.

4. No loss of power on kerosene.

5. Cuts running cost practically in half.

6. Will run on straight petrol with equal satisfaction.

The exceptional results secured with this Ronaldson Tippett Patent is a revelation not only to the average user but to engineers of wide experience.