Robinson Patent Hot Air Engine

You could say that our family Robinson Hot Air Engine started off my obsession with hot air engines which has grown over the years.

I made this video in 2022. Enjoy

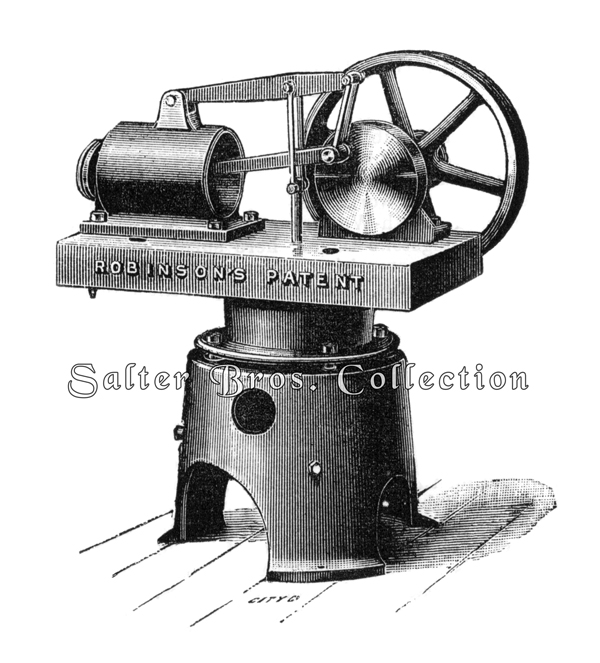

Robinson’s Patent Air Engine.

The air engine which we illustrate by the accompanying engravings takes a place for small powers where it is undesirable to have the difficulties of a small steam or gas engine and where an engine without delicate mechanism is required.

The engine is remarkably simple in character, the main ideas involved in its design being most ingeniously carried out. Although it ignores some of the refinements which killed the earlier and larger caloric, or hot air engines, it possesses important points which, it is claimed, make it a practical success.

These engines can be worked either by coal or coke or gas, and the absence from complicated mechanism is readily seen from the engravings. The temperature of the working cylinder is so low that the wear and tear of it and the piston is, we are informed, almost nil; and this is shown by the fact that the oil required is reduced, it is said to a nominal quantity.

When gas is not used a coal fire of slow combustion is employed with great economy, and the smaller sizes of engines may be worked when required by oil lamps.

There is no internal combustion or ignition in the cylinder, so that the parts are not subjected to dirt or shock. A steady impulse is given to the piston at each revolution of the engine.

How does it work?

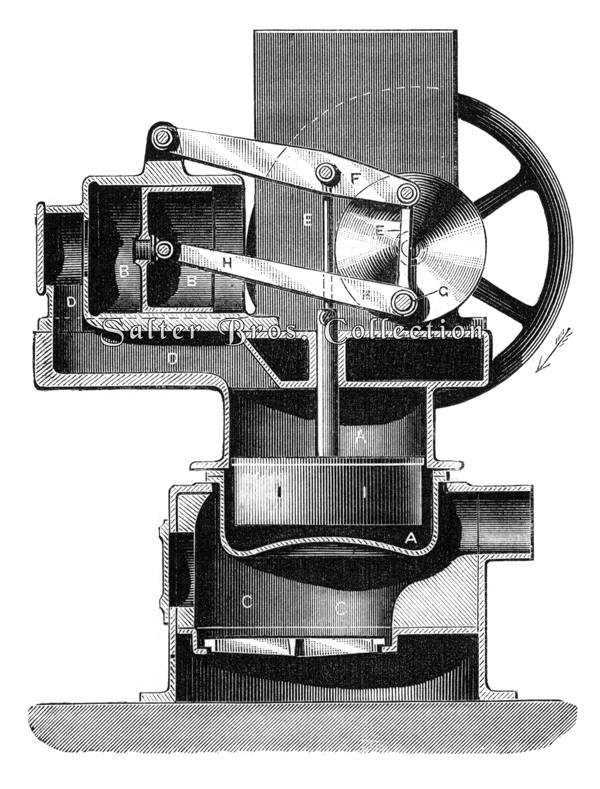

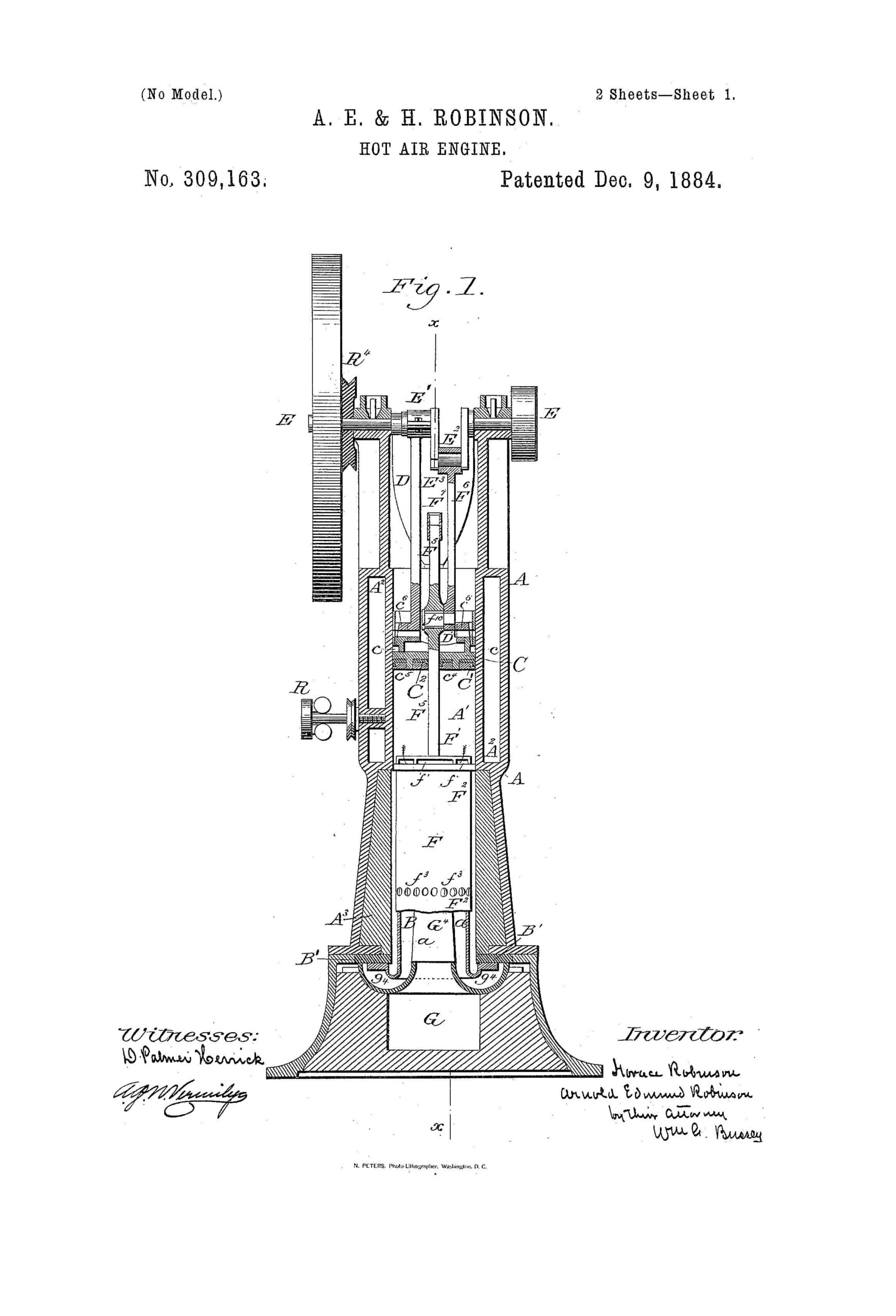

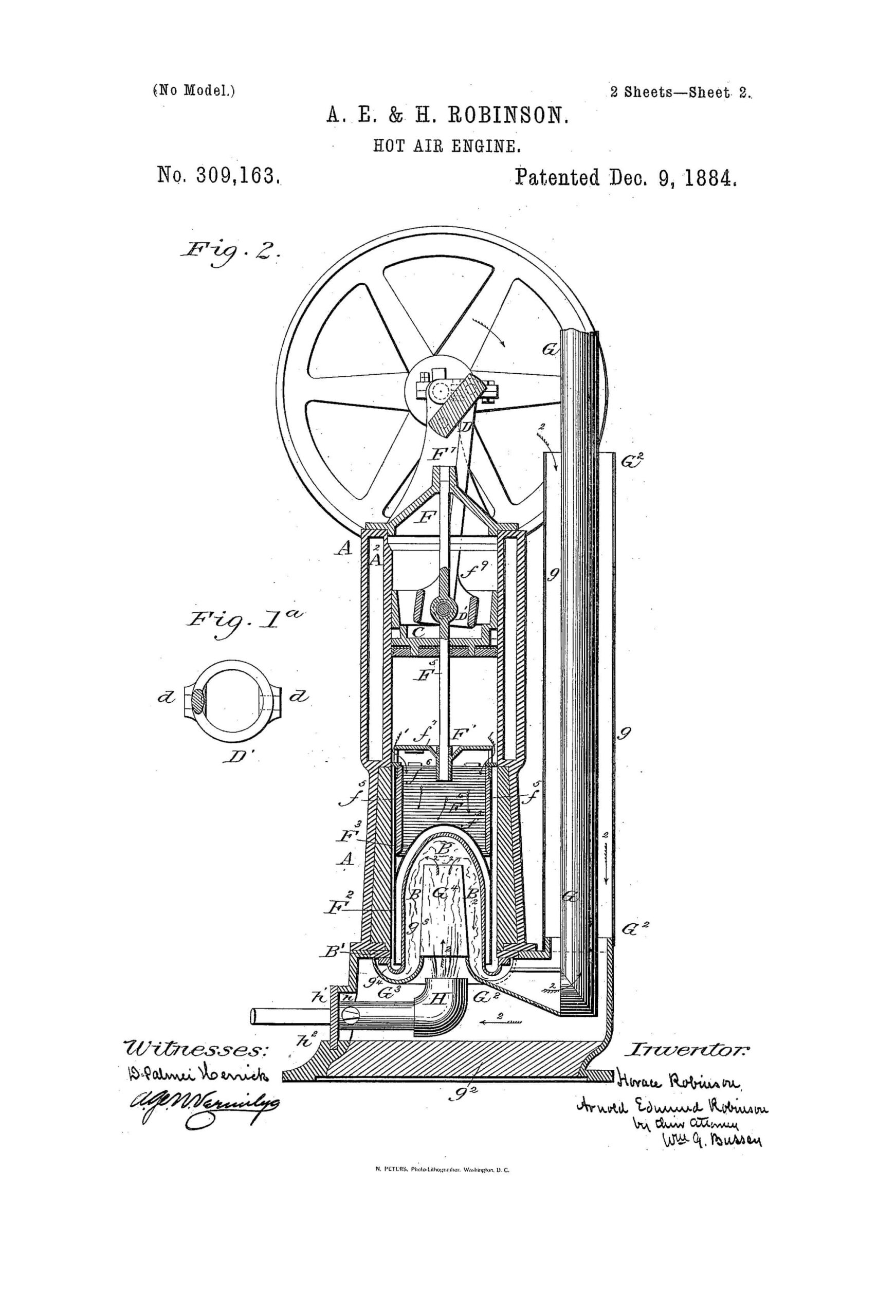

The action of the engine is as follows: – Referring to the section, A is the air chamber, which is heated at its lower end by a slow combustion fire within C, or by gas or otherwise as before mentioned; B is the working cylinder, D is a passage leading from the air chamber A to the working cylinder B.

The Piston B is thus free to be acted upon by any change of pressure which takes place within the air chamber A; “i” is the so-called “Regenerator,” for heating and cooling air.

The crank G is driven by the piston B by the direct connecting rod H, and the same crank pin drives the regenerator “i” by the means of the links E, the lever F, and the links E.

A plain balanced disc can thus be used to balance the moving parts, and it will be seen that as the reciprocating parts are moving at right angles to each other, the balancing can be done more perfectly that would otherwise be possible.

The arrangement of the engine renders the parts easy of access. The upward action of the regenerator causes the air to be heater and the downward action has a cooling effect.

Assuming the engine to be in the position shown in the section, the regenerator has been lowered by gear E, F, E, and crank pin G, and the air is consequently cooled, the piston is therefore making its in stroke.

The regenerator is then raised, heats and expands the air, and the piston is forced outwards, and the action is repeated.

The engine is easy to start and stop, and will work long runs almost without attention.

These engines have now, it is said, been tested in practical use with satisfactory results, and may be seen working at Messrs. A. E. and H. Robinson’s, Great Bridge-water-street, Manchester, and in other places.

Some of the engines are arranged with vertical cylinders.

They are made in several sizes, up to about 4-man power.

Robinson Engine Internals

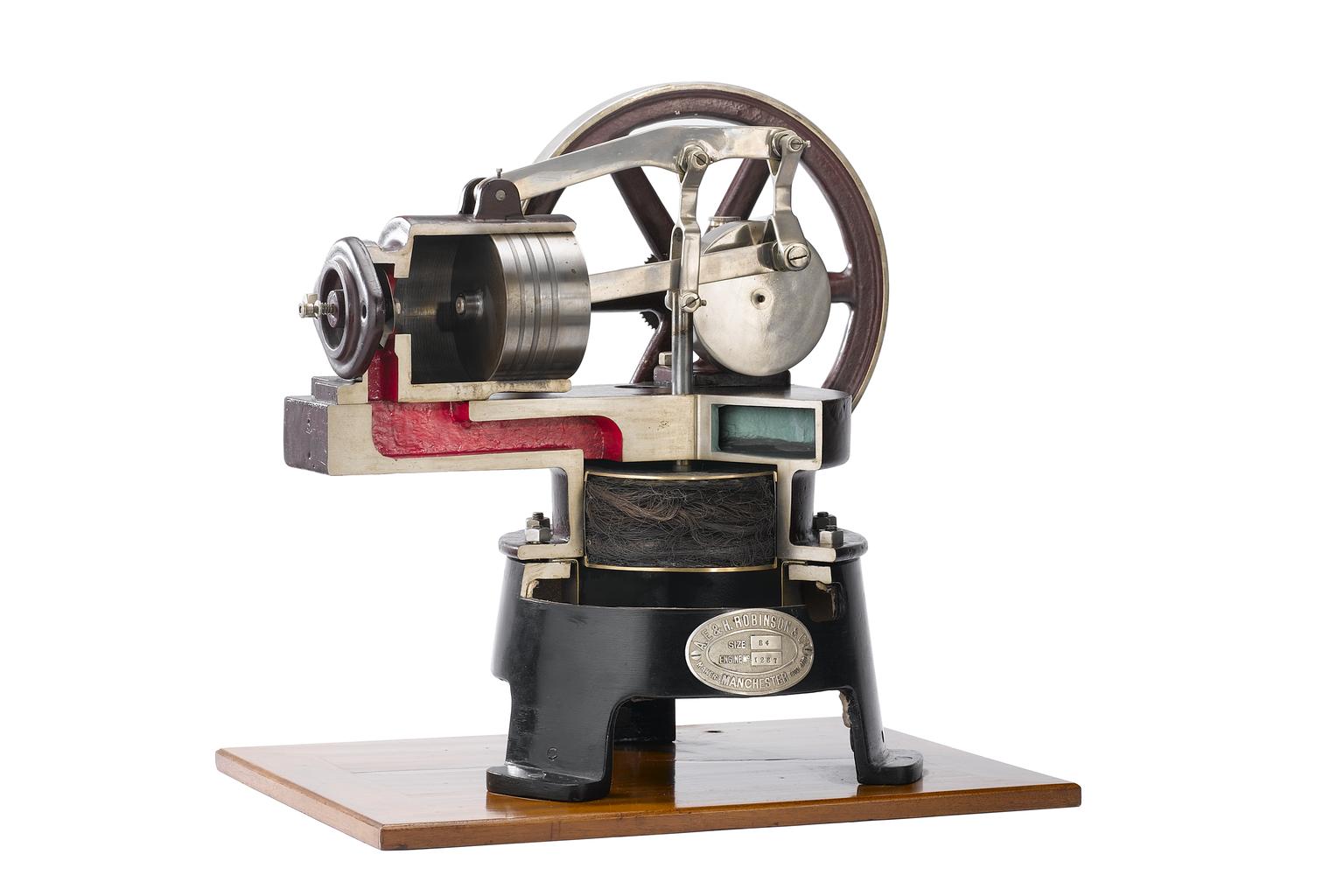

To the right you can see a sectioned Robinson Patent Hot Air Engine.

This particular engine is a later model B4 engine which was produced under licence by Gardner Engines.

Things to note:

The red painted area is where the air travels between the two cylinders with the regulation valve / over-speed valve on the front of the cold cylinder.

The cold piston does not run rings but has oil grooves that fill with oil to hold in the compression,

The blue area is the water jacket which aids in the cooling of the area. Note that the water jacket extends around the red air chamber to promote the difference in temperature.

The packing material that fills the displacer piston is to keep the heat in.

Sectioned Robinson Engine – Photo Credit – Science Museum Group UK

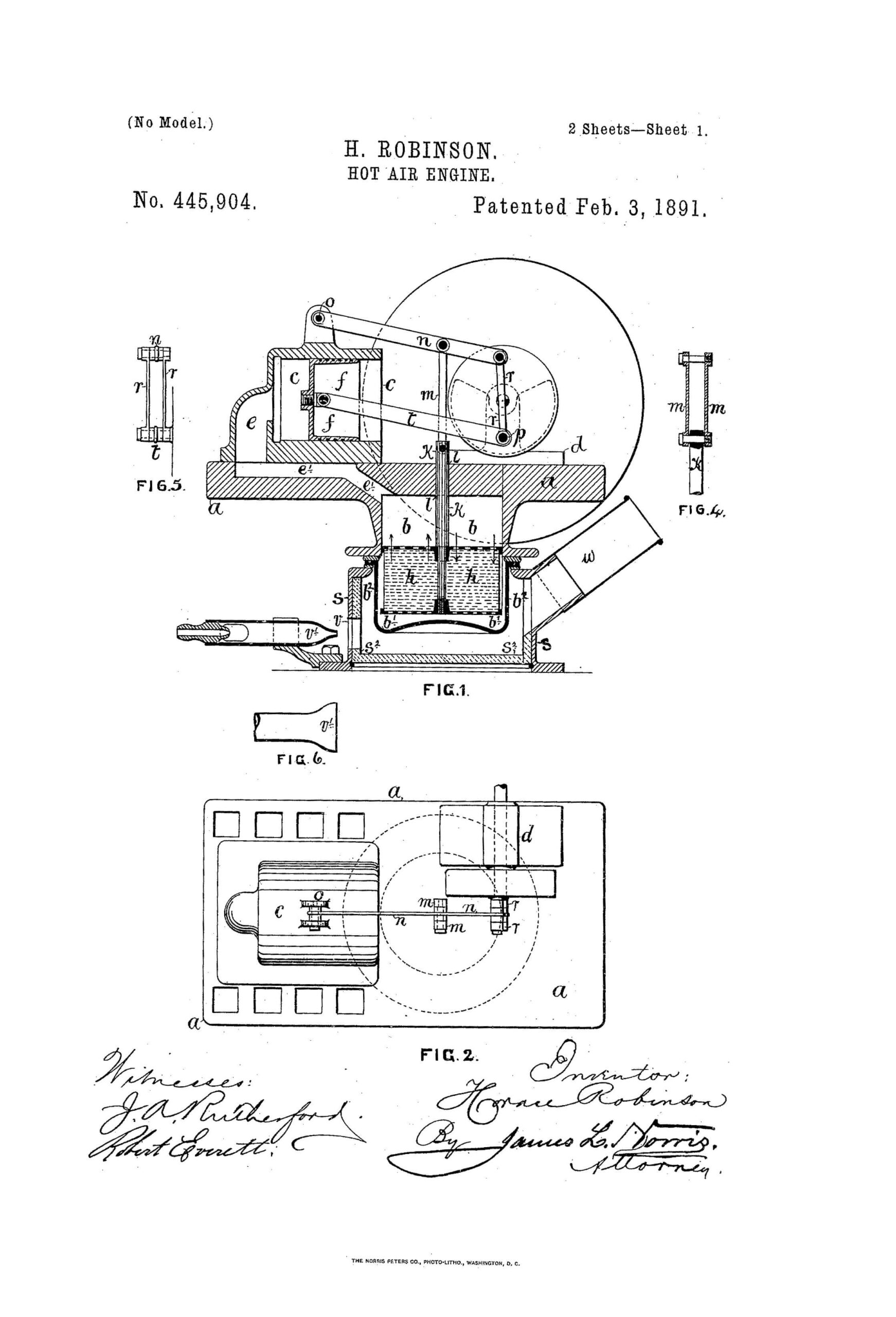

Registered Patents

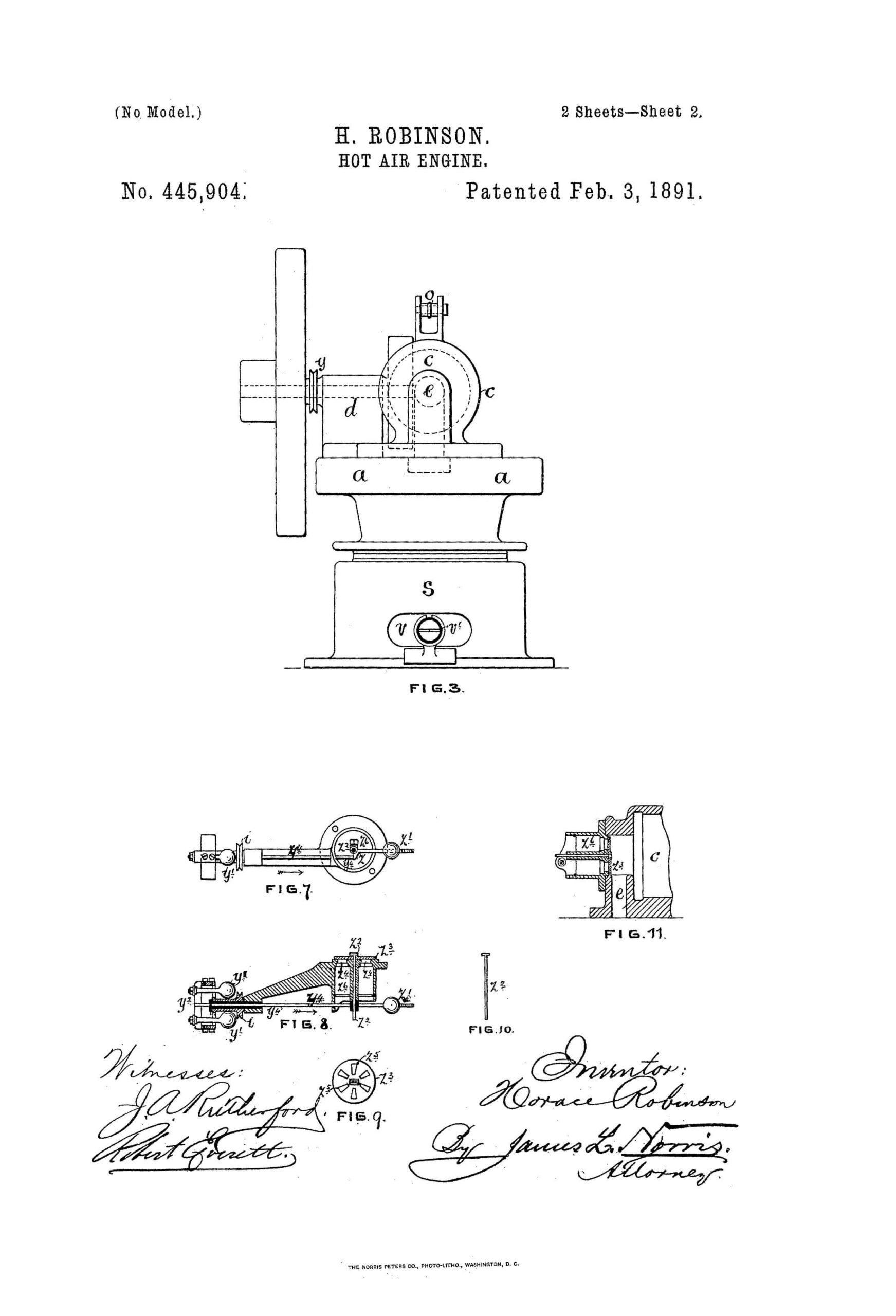

American Patent No. 445,904 & No. 309,163

Patent Information – Google Patents