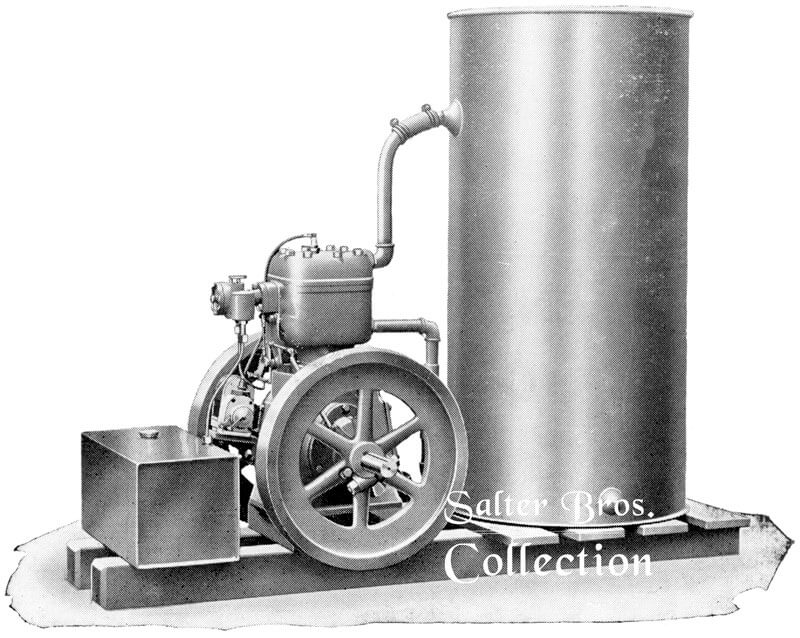

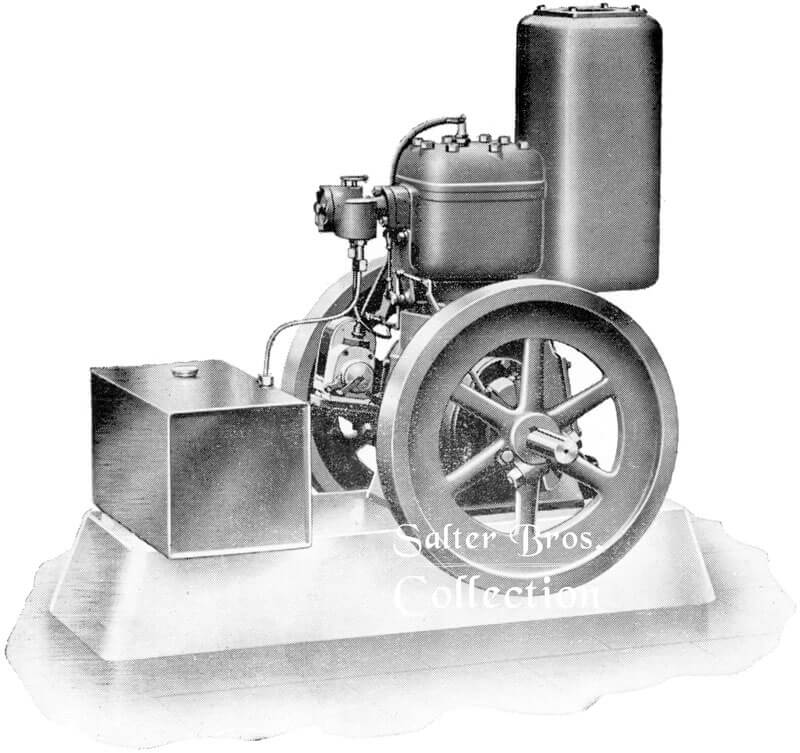

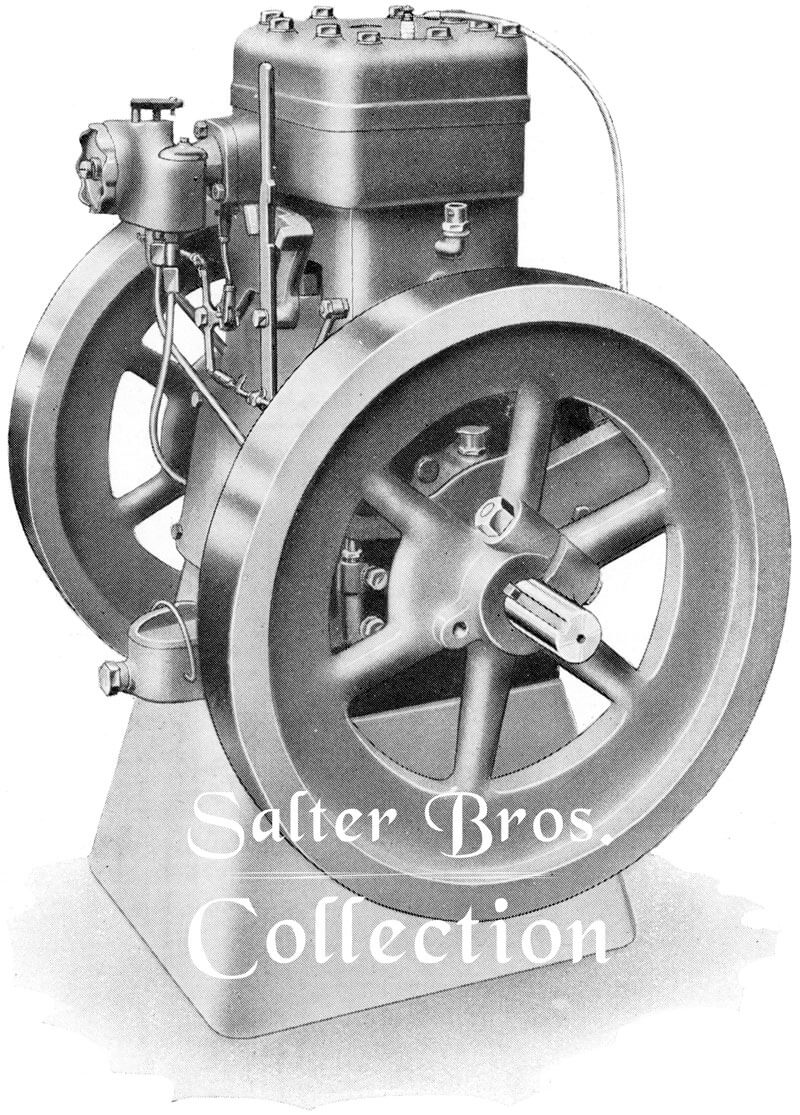

Ronaldson Tippett – Type G

The Ronaldson Tippett Type G, was available in 3 ½ and 4 ½ B.H.P.

Totally enclosed with all main working parts running in an oil bath. Made on lines to ensure the longest life with a minimum of duplicates and the greatest reliability with the least attention.

It is easy to appreciate that the wonderful success of Ronaldson Tippett Engines could not have been achieved unless they combined many unusual and exclusive constructional features, together with workmanship of the very highest grade.

If you could only see a Ronaldson Tippett Engine in the making and follow, step by step, the process and stages by which raw material is transformed into an Engine of enduring strength and reliability, you would understand just why it is possible for Ronaldson Tippett engines to stand up to years of the toughest kind of service with the minimum of cost for duplicates.

The Ronaldson Tippett engine is thoroughly modern in design, with all working parts completely enclosed and working in oil. The bottom of the crankcase forms an oil reservoir, and when this is filled the engine thereafter automatically looks after its own lubrication. The lower end of the connecting rod picks up and splashes oil from the sump onto the bearings, piston and cylinder walls.

The advanced feature of design ensures that sand, dust or grit does not get into the working parts, and does away with the main cause of wear, loss of power, and repair expense.

Cylinders are made in chrome nickel alloy iron, which is not only an exceedingly close-grained metal, but has great extra strength. Cylinders are roll-finished under pressure, producing a glass-hard and smooth surface, with the cylinder bores true to one-thousandth of an inch.

Crankshafts are forged from high tensile steel, and finished in a modern grinding machine.

Main Bearings are of special white metal die castings, produced under several hundred pounds pressure. They are of unusually big proportions.

Connecting Rod is of special steel. Big end bearing is lined with nickel hardened white metal. Gudgeon bearing is in phosphor bronze. Both big end and gudgeon bearings are adjustable for taking up wear.

Piston is in chrome nickel alloy iron and has case-hardened steel gudgeon pin. Piston rings are of highest grade, made from special metal.

Ignition is by genuine “Bosch” magneto. As the ignition of the engine is vital, the greatest reliability is ensured by the adoption of this famous magneto.

Governor is of the flyball type, ensuring exceptionally steady running under all conditions. These engines are particularly suited to driving machines where a very steady-running engine is essential.

Carburettor is of an improve type, simple in design – no floats, weights or jiggling needle valves.

Engine Design embodies latest high turbulence L head, ensuring high efficiency and absence of valve trouble. This design not only guarantees low running cost, but enables engines to maintain their power under the most exacting conditions.

These Engines will use second=grade benzine, and because of their highly efficiency design will run cheaper than many kerosene engines.

Case-hardened Parts are embodied where desirable, while special alloy steels are used at many points, Nothing has been spared in design, material or workmanship to produce an Engine which is not only well suited to Australian conditions, but ensures long life, reliability and low running cost.

Behind this Engine is the service of reputable and experienced manufacturers in Australia, noted for their straight forward business methods, and lasting practical interest in every Engine sold.

Engine is available in tank cooled or hopper cooled.